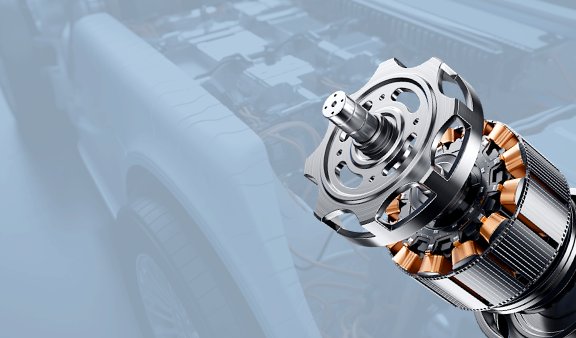

NdFeB magnet motors are widely used in almost all fields of aviation, aerospace, national defense, equipment manufacturing, industrial and agricultural production and daily life. It includes permanent magnet synchronous motors, permanent magnet generators, DC motors, AC permanent magnet servo motors, permanent magnet linear motors, special permanent magnet motors and related control systems, covering almost the entire motor industry. Mechanism and Principle of Rare-Earth Permanent Magnet Motor The structure of rare-earth permanent magnet synchronous motor mainly consists of rotor, end cover, stator and so on. Generally speaking, the stator structure of permanent magnet synchronous motor is very similar to that of ordinary induction motor, but its unique rotor structure is mainly different from other motors.

Due to the excellent magnetic properties of neodymium magnet material, a permanent magnetic field can be established without additional energy after magnetization. Replacing the traditional electric field of the motor with a rare earth permanent magnet motor is not only highly efficient, but also simple in structure, reliable in operation, small in size and light in weight. It can not only achieve high performance (e.g. ultra-high efficiency, ultra-high speed, ultra-high response speed) that traditional electric excitation motors can not match, but also make it meet the specific operating requirements of special motors, such as elevator traction motors and automobile motors. Rare-earth permanent magnet motors combined with power electronics technology, microcomputer control technology, so that the performance of permanent magnet rotor and transmission system to a new level. Therefore, improving the performance and level of supporting technology and equipment is an important development direction for the automobile industry to adjust its industrial structure.

Motor field