Processes

Combination of proprietary technology and modern production techniques

01

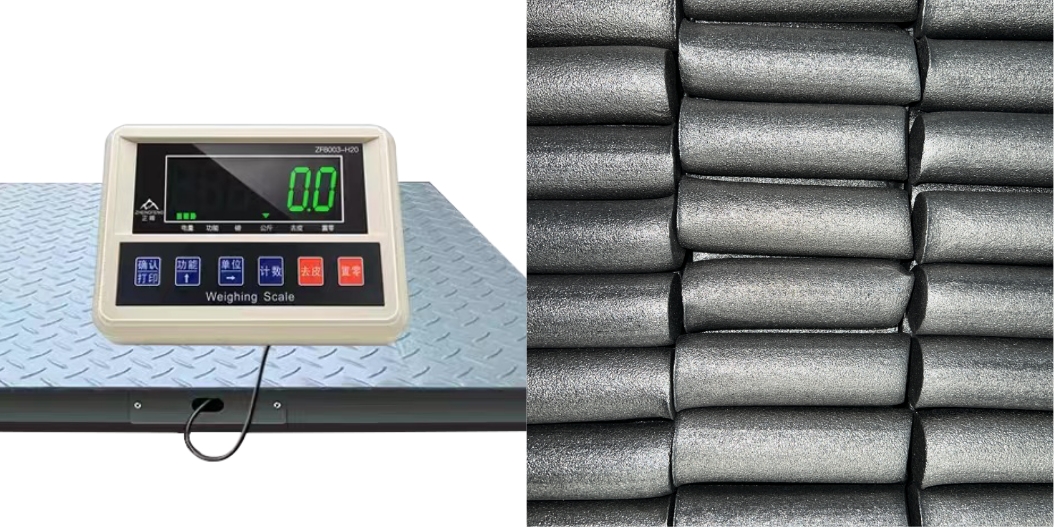

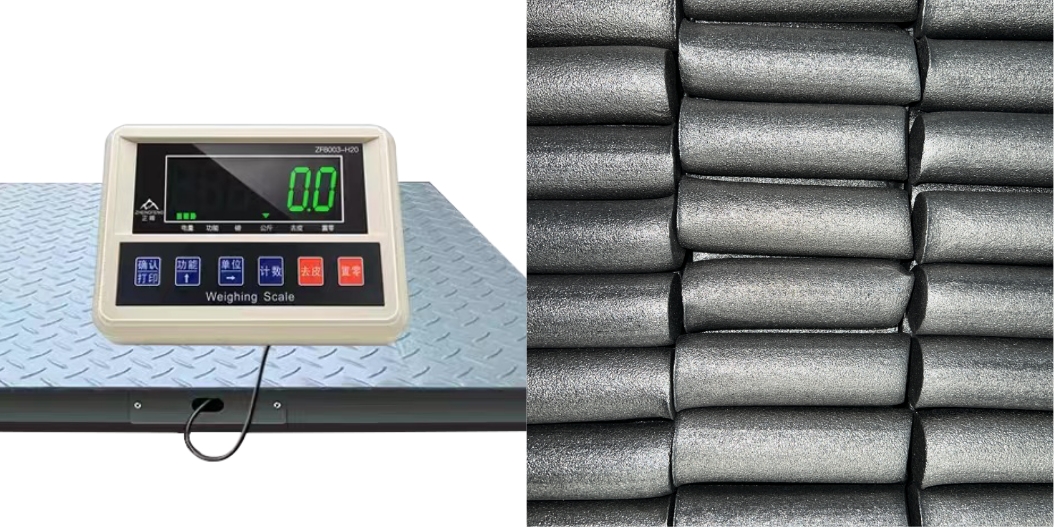

Preparation of raw materials according to recipe ratios

02

Melting and flaking

03

Hydrogen crushing and air flow milling

04

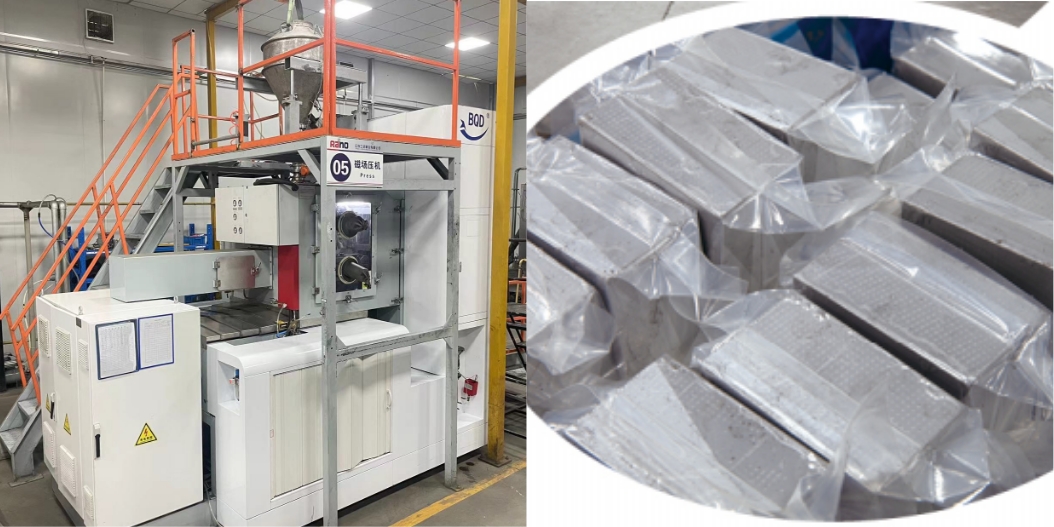

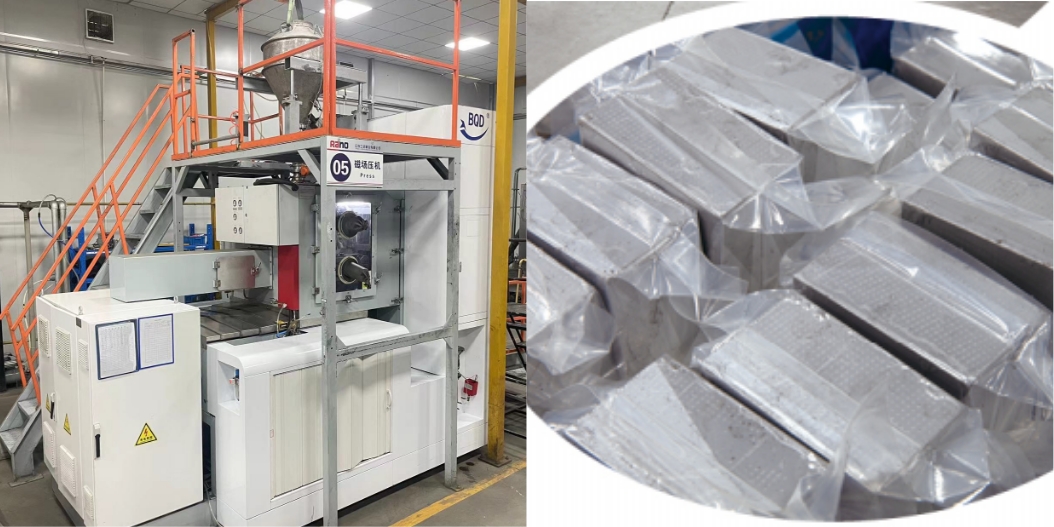

Blank Forming and Orientation in Magnetic Fields

05

Sintering & Ageing

06

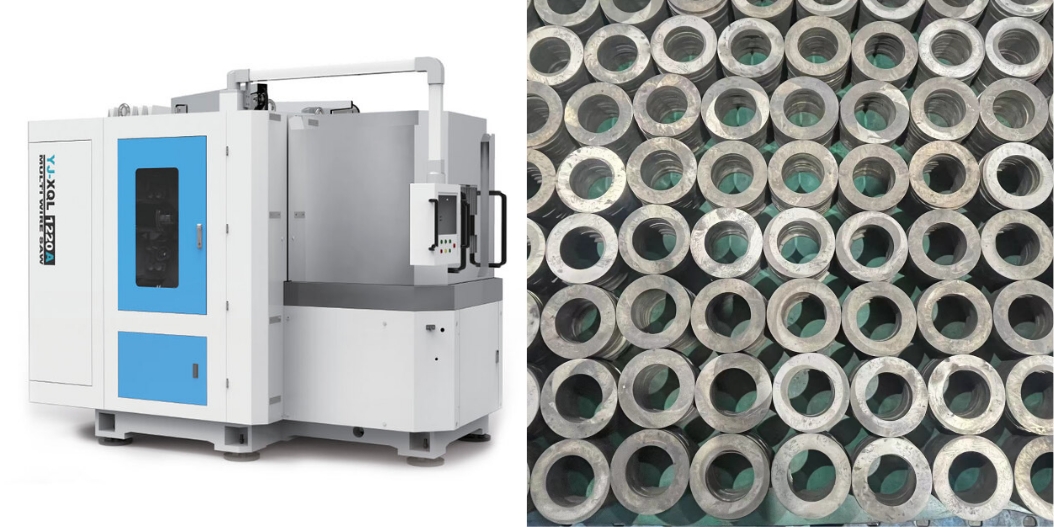

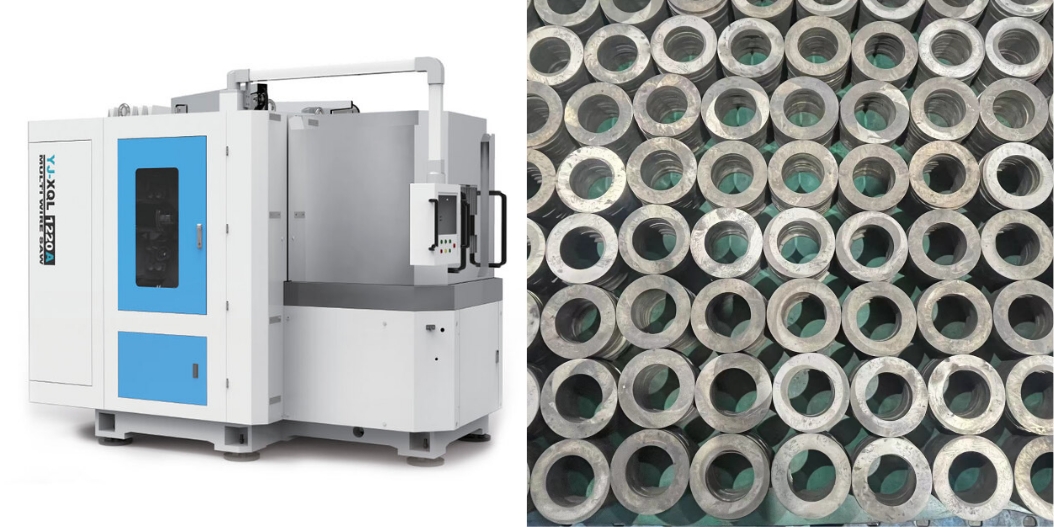

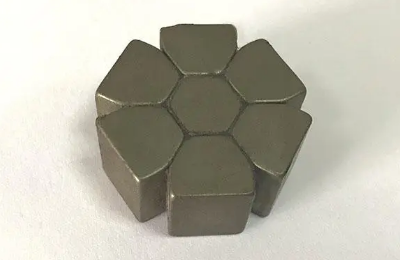

Machining

07

Electroplated

08

Product saturation magnetization

09

Packaging and transportation

IQC

Analyze alloy structure and composition

Examining particle size and particle size distribution

Checking the dimensions and perpendicularity of the blank

Detection of sintered dimensions and magnetic properties

Inspection of dimensional accuracy

Detecting Flux

Inspection of appearance, etc.

Packaging and transportation

Processes

01

Preparation of raw materials according to recipe ratios

IQC

02

Melting and flaking

Analyze alloy structure and composition

03

Hydrogen crushing and air flow milling

Examining particle size and particle size distribution

04

Blank Forming and Orientation in Magnetic Fields

Checking the dimensions and perpendicularity of the blank

05

Sintering & Ageing

Detection of sintered dimensions and magnetic properties

06

Machining

Inspection of dimensional accuracy

07

Electroplated

Detecting Flux

08

Product saturation magnetization

Inspection of appearance, etc.

09

Packaging and transportation

Packaging and transportation

Quality control

Quality objective

Quality objective

≥98 points

Job satisfaction

Customer satisfaction ≥ 98 points

≤2 pieces

Customers claim

Customer complaints ≤ 2 per month

100%

Yields

100% yield rate of finished product shipment

100%

Satisfactory rate

Main raw materials sampling inspection pass rate 100%

98%

98%

98% pass rate for rough inspection lots

≥98%

Satisfactory rate

Outside processing lot pass rate ≥98%

Performance and Parameters

Physical properties of sintered NdFeB materials

Physical properties of surface treatment and use environment

Sintered NdFeB Magnetic Properties Parameter Table

| Items | Parameter Values | Unit |

| Curie Temperature | 310~380 | ℃ |

| Relative Recoil Permeability | 1.02~1.05 | |

| Reversible Temperature Coefficient of Br (20~100℃) | -0.09~-0.13 | %/℃ |

| Reversible Temperature Coefficient of Hcj (20~100℃) | -0.4~-0.7 | %/℃ |

| Density | 7.50~7.70 | g/cm3 |

| Vickers Hardness | 550~700 | |

| Bending Strength | -0.09~-0.13 | MPa |

| Tensile Strength | ≥80 | MPa |

| Compressive Strength | 800 ~1050 | MPa |

| Electric Resistivity | 150 | μΩ·cm |

| Thermal Conductivity | 8~10 | W/(M·℃) |

| Coefficient of Thermal Expansion (Parallel to the orientation) | 5 | 10-6/K |

| Coefficient of Thermal Expansion (vertical to the orientation) | -1.5 | 10-6/K |

| Young's Modulus | 150~200 | GPa |

| (20℃~320℃)Specific Heat(20℃~320℃) | 3.0~4.6 | J/(g·k) |

| weight loss(low weight loss products) | ≤2 | mg/cm2 |

| Coating Material | Colour | Properties | Environment of Application | Thickness of Coating layer |

| Zine | Blue, Black and rainbow etc | Compact, Stable and Homogeneous | With reasonalbe capability of anticorrosion | |

| Nickel-Copper-Nickel | White and black | Light and Stable | Suitable for higher corrosive environment | |

| Phosphorization | Colorless or light gray | Uniform thickness | Short-term anticorrosion | |

| Epoxy | Black and Gray | layer with certain luster, insurability | Suitable for higher corrosive environment | |

| Parylene | Transparency | Uniform thickness, density pinholes- free and insurability | Excellent capability of anticorrosion especially for small items | |

| Ni+Cu+Epoxy | Black | Layer with certain luster insurability and stability | Excellent capability ofanticorrosion. Suitable for hostile environment salt spray resistance>300hr | |

| Al+Epoxy | Black | Layer with certain luster insurability and stability | Excellent capability of anticorrosion. Suitable for hostile environment Salt spray resistance>650hr Widely used in EV industry. |

| Grade | (Br)KGs | (Hcb)KOe | (Hcj)KOe | (BH)maxMGOe | Hk/Hcj | (T)℃ |

| N33 | 11.4~11.8 | ≥10.5 | ≥12 | 31~35 | ≥95 | 80℃ |

| N35 | 11.8-12.3 | ≥11 | ≥12 | 33~37 | ≥95 | 80℃ |

| N38 | 12.3~12.7 | ≥11.2 | ≥12 | 36~40 | ≥95 | 80℃ |

| N40 | 12.7~12.9 | ≥11.4 | ≥12 | 38~42 | ≥95 | 80℃ |

| N42 | 12.9~13.3 | ≥11.5 | ≥12 | 40~44 | ≥95 | 80℃ |

| N45 | 13.3~13.7 | ≥11.6 | ≥12 | 43~47 | ≥95 | 80℃ |

| N48 | 13.7~14.0 | ≥11.6 | ≥12 | 45~49 | ≥95 | 80℃ |

| N50 | 13.9~14.2 | ≥11.4 | ≥12 | 48~52 | ≥95 | 80℃ |

| N52 | 14.2~14.5 | ≥10.2 | ≥11 | 49~53 | ≥95 | 80℃ |

| N54 | 14.4 14.8 | ≥10.2 | ≥11 | 50~54 | ≥95 | 80℃ |

| 35M | 11.8~12.3 | ≥10.9 | ≥14 | 33~36 | ≥95 | 100℃ |

| 38M | 12.3-12.6 | ≥11.5 | ≥14 | 36~40 | ≥95 | 100℃ |

| 40M | 12.6~12.9 | ≥11.8 | ≥14 | 38~42 | ≥95 | 100℃ |

| 42M | 12.9 13.3 | ≥12.0 | ≥14 | 40~44 | ≥95 | 100℃ |

| 45M | 13.3~13.7 | ≥12.5 | ≥14 | 43~46 | ≥95 | 100℃ |

| 48M | 13.6~14.0 | ≥12.9 | ≥14 | 45~49 | ≥95 | 100℃ |

| 50M | 13.9~14.2 | ≥13 | ≥ 14 | 47~51 | ≥95 | 100℃ |

| 52M | 14.2~14.6 | ≥12.5 | ≥13 | 49~53 | ≥95 | 100℃ |

| 35H | 11.8~12.3 | ≥11 | ≥17 | 33~37 | ≥95 | 100℃ |

| 38H | 12.3~12.6 | ≥11.4 | ≥17 | 36~40 | ≥95 | 120℃ |

| 40H | 12.6~12.9 | ≥11.7 | ≥17 | 38 ~42 | ≥95 | 120℃ |

| 42H | 12.9~13.3 | ≥12.0 | ≥17 | 40 ~44 | ≥95 | 120℃ |

| 45H | 13.3~13.7 | ≥12.5 | ≥17 | 43~47 | ≥95 | 120℃ |

| 48H | 13.7~13.9 | ≥12.8 | ≥16 | 45 ~49 | ≥95 | 100℃ |

| 50H | 13.9~14.2 | ≥12.9 | ≥16 | 47~51 | ≥95 | 100℃ |

| 52H | 14.2~14.5 | ≥12.8 | ≥16 | 48 ~53 | ≥95 | 100℃ |

| 33SH | 11.4~11.9 | ≥10.5 | ≥20 | 31~35 | ≥92 | 150℃ |

| 35SH | 11.8-12.3 | ≥11.2 | ≥20 | 33~37.5 | ≥92 | 150℃ |

| 38SH | 12.3~12.6 | ≥11.3 | ≥20 | 36.5~40 | ≥92 | 150℃ |

| 40SH | 12.6~12.9 | ≥11.8 | ≥20 | 38~41 | ≥92 | 150℃ |

| 42SH | 12.9~13.3 | ≥12.4 | ≥20 | 40~44 | ≥92 | 150℃ |

| 45SH | 13.3~13.7 | ≥12.5 | ≥20 | 43~46 | ≥92 | 150℃ |

| 48SH | 13.7~14.0 | ≥12.8 | ≥20 | 45~49 | ≥92 | 150℃ |

| 50SH | 13.9~14.2 | ≥12.9 | ≥20 | 47~51 | ≥92 | 150℃ |

| 52SH | 14.2~14.5 | ≥12.8 | ≥19 | 48~53 | ≥92 | 150℃ |

| 30UH | 10.8~11.4 | ≥9.5 | ≥25 | 28~32 | ≥90 | 180℃ |

| 33UH | 11.4~11.8 | ≥10.3 | ≥25 | 31~34 | ≥90 | 180℃ |

| 35UH | 11.8~12.3 | ≥10.6 | ≥25 | 33~37 | ≥90 | 180℃ |

| 38UH | 12.3~12.6 | ≥11.1 | ≥25 | 36~39 | ≥90 | 180℃ |

| 40UH | 12.6~12.9 | ≥11.5 | ≥25 | 38~41 | ≥90 | 180℃ |

| 42UH | 12.9~13.3 | ≥11.8 | ≥25 | 40~43 | ≥90 | 180℃ |

| 45UH | 13.3~13.7 | ≥12.2 | ≥24 | 43~46 | ≥90 | 180℃ |

| 48UH | 13.7~14.2 | ≥12.5 | ≥24 | 45~49 | ≥90 | 180℃ |

| 50UH | 13.9~14.3 | ≥12.8 | ≥24 | 47~51 | ≥90 | 150℃ |

| 52UH | 14.2~14.5 | ≥13.1 | ≥24 | 48~53 | ≥90 | 180℃ |

| 30EH | 11.0~11.4 | ≥9.5 | ≥30 | 28~31 | ≥90 | 200℃ |

| 33EH | 11.4~11.8 | ≥10.3 | ≥30 | 31~34 | ≥90 | 200℃ |

| 35EH | 11.8~12.2 | ≥11.1 | ≥30 | 33~36 | ≥90 | 200℃ |

| 38EH | 12.2~12.5 | ≥11.6 | ≥30 | 35~39 | ≥90 | 200℃ |

| 40EH | 12.5~12.8 | ≥11.9 | ≥30 | 37~41 | ≥90 | 200℃ |

| 42EH | 12.8~13.1 | ≥12.2 | ≥29 | 39~43 | ≥90 | 200℃ |

| 28TH | 10.5~10.8 | ≥9.5 | ≥35 | 26~29 | ≥90 | 230℃ |

| 30TH | 10.8~11.4 | ≥10.1 | ≥35 | 28~31 | ≥90 | 230℃ |

| 33TH | 11.4~11.8 | ≥10.2 | ≥35 | 31~34 | ≥90 | 230℃ |

| 35TH | 11.8~12.2 | ≥10.6 | ≥35 | 33~36 | ≥90 | 230℃ |

| 38TH | 12.2~12.5 | ≥11.6 | ≥33 | 35~39 | ≥90 | 230℃ |

Magnetism FAQ

Neodymium Iron Magnets Coating - Parylene

Rano Magnetics: Warm Wishes for a Brilliant New Chapter

Working Principle of the Hall Element

Rano R&D of HRE-Free Magnets

Eddy Current Loss in Rare Earth Permanent Magnet Materials

Basic Concepts of Permanent Magnet Materials

NdFeB Magnets - Dimensional & Geometric Tolerances

Service Life of NdFeB—Long-Term Stability of Permanent Magnets

The difference between conventional process NdFeB magnets and cerium-containing magnets

Neodymium-Iron-Boron Surface Treatment Solution -- Passivation

Physical Properties of Sintered NdFeB Magnets

Neodymium iron boron magnet in 3C products

Magnetic Separator and Permanent Magnet

Sintered NdFeB Multi-Pole Magnetization Technology

What is the Magnetic Moment?

Orientation and Magnetization of Sintered NdFeB Magnets

The Suction Force of Magnets

Grades and Properties of Sintered NdFeB Permanent Magnets

How can You Successfully Transport Magnets by Air?

Sintered NdFeB Forming Process

Types of Permanent Magnet Materials

Temperature Stability of Permanent Magnets

Three Methods of Demagnetization

Meaning of Sintered NdFeB Grades

Heilbeck Array

Magnets in Loudspeakers

Common Plating for Magnets

Common Pre-Energy Vehicle Motors

Surface Magnetization, Remanent Magnetization and Magnetic Flux

Magnetism FAQ