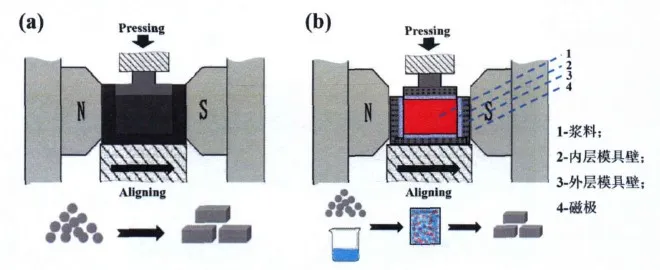

Compared with the traditional powder metallurgy process, the forming of NdFeb has two major characteristics: magnetic field orientation and oxidation protection, the forming process basically determines the geometry, size and orientation of the magnet, which is the key link in the preparation of sintered NdFeb, forming is generally divided into dry pressing and wet pressing two categories.

Figure 1. Dry forming (a) and wet forming (b)

A. Wet molding technology

Wet molding techniques are widely applied in the field of functional ceramics. In 2001, Hitachi Company prepared a high-performance magnet with a remanence (Br) of 1.46 T (14.6 kG) and a coercivity (Hcj) of 1.20 MA/m (15.1 kOe) by adding methyl oleate, a surfactant, using mineral oil as a solvent. The lubrication provided by organic reagents can enhance the fluidity and orientation of the powder, thereby preparing a compact with high uniformity. However, the wet forming process is complex and inefficient. During the sintering process, a large amount of solvent release can damage the vacuum system, and residual carbon can affect the magnet's performance. Consequently, the wet forming method has been gradually abandoned.

B.Dry molding technology

After years of practice and improvement by personnel, has become the preferred method for large-scale production. The magnetic field orientation of the magnetic powder in the mold cavity of a certain shape is achieved by the closure of the indenter. However, as the green density increases, the orientation inevitably suffers some damage. Dry molding can be divided into parallel pressing and vertical pressing based on the relationship between the magnetic field direction and the pressing direction. The vertical pressing method is more widely used due to its minimal damage to powder orientation. In China, the two-step pressing method is predominantly used, pressing the green density to 3.8-4.1g/cm³, followed by isostatic pressing at approximately 180MPa to increase the compact density to about 4.5g/cm³ without destroying the existing orientation level. This method allows for the use of various molds, such as automatic and combined molds, resulting in high production efficiency and stable performance.

However, the vertical pressing, isostatic pressing, post-grinding, and slicing methods have several disadvantages: (1) Due to limitations in billet deformation and oxide layer formation, the blank processing allowance is large, leading to low material yield; (2) The secondary pressing method requires vacuum plastic sealing after the green stage, resulting in a long process cycle and low automation degree; (3) The orientation degree can still be damaged during the molding process. A company is currently working to improve by mainly canceling the isostatic pressing and automating the sintering process. The second improvement is to use non-compression molding and other methods to further enhance orientation. Additionally, for products like tiles, rings, wafers, and various complex shapes, the development of near-final molding processes and non-processing molding processes allows for the direct production of the final product shape, equal or close to the desired product.

1. Single molding process

By increasing the pressure during molding, the green density can be raised to more than 4.2 g/cm³, and after suppressing, the automatic molding press can be canceled. The manipulator automatically transfers the compact into the sintering box pattern, and the sealing is done under inert gas protection, channeling it into a continuous sintering furnace. Charging is done via a flashboard valve, enabling automated production, reducing labor costs, and conducting the entire process in a low-oxygen environment, which is beneficial for the stability of the process and performance.

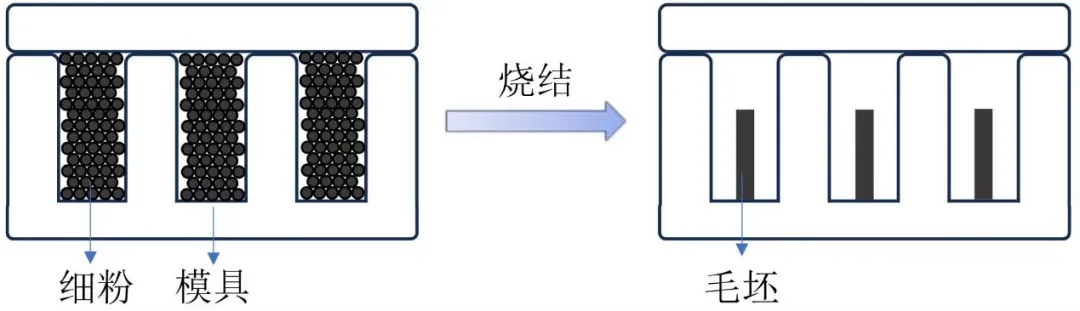

2. Pressureless compacting

Figure 2. No pressure forming

In order to eliminate the damage to the orientation during the molding process, the orientation is carried out in the loose or micro-pressure state, and the vacuum or high pressure sintering is carried out with the mold. This method has high requirements on mold material, permeability and inner cavity wall roughness, but because the powder gap is too large, it is difficult to densify only by capillary action in the sintering process, and it is easy to shrink and deform.

3. Isostatic pressure pulsed magnetic field forming of rubber film

The rubber mold filled with magnetic powder is placed in the metal mold, and the rubber film and magnetic powder are compressed by the metal indenter through the pulsed magnetic field orientation. Due to the limitation of the metal mold cavity, the rubber mold expands to the inner cavity, and the isostatic pressure is applied to the powder sample. Because there is no relative movement between the inner wall of the mold cavity and the powder, the orientation is well maintained. However, due to the difference of hardness and Young's modulus between rubber film and steel mold, the compact is easy to produce non-uniform deformation.

4. Near-net-shape forming process (single-piece pressing)

The orientation of the magnetic field in parallel pressing machines is the same as the pressing direction, thus the degree of orientation damage is much higher than that of vertical pressing. Moreover, due to the limitations of the size of the orientation pole head, the product pressing area is smaller. However, due to the advantages of feeding and orientation, the parallel pressing method can press round, ring, special-shaped, and single-piece products in one near-net shape forming process, with high pressing accuracy, good consistency of magnetic properties, reduced machining allowance, and improved material utilization. Nevertheless, the single-piece pressing process has higher requirements for powder flowability, the press (servo control accuracy, magnetic field size and uniformity, automatic powder distribution, etc.), molds, and sintering processes.

5. 3D printing technology

Figure 3. 3D Printing

3D printing is an additive manufacturing technology that constructs parts by layer-by-layer printing of powdered metals. If regional-oriented magnetic fields can be used to orient the main phase grains and low-temperature molten boundary phase particles encapsulate the main phase grains to achieve densification of the magnet, theoretically, it should be possible to achieve near-net shape forming of various sizes and complex shapes of magnets with high orientation and uniform grain boundary distribution. At the same time, the preparation of radiation magnetic rings, obliquely charged magnets, and other products would no longer be difficult. Therefore, as soon as 3D printing technology was introduced, it attracted the attention of rare earth permanent magnet researchers. However, apart from aiding sintering and densification, the boundary phase plays a significant role in magnetic properties, especially in coercivity. Currently, the mechanism by which the composition, distribution, and crystal structure evolution of the boundary phase affect magnetic properties has not been fully revealed. The design of the secondary particle composition and grain boundary size still requires the efforts of technical development personnel.