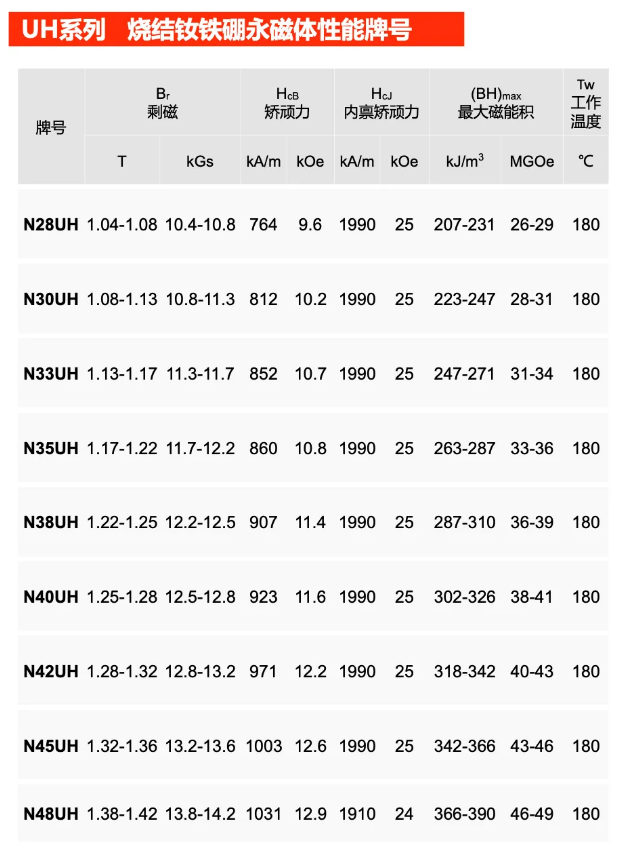

Sintered NdFeB permanent magnets can be classified into seven series based on their intrinsic coercivity (HcJ): N, M, H, SH, UH, EH, and AH (TH). Within each series, specific grades are further subdivided according to the magnet's remanence (Br) and maximum energy product (BH)max.

Grade Naming Convention:

● The numerical value indicates the magnet's maximum energy product (BH)max - a higher number represents a greater maximum energy product.

● The letter designation reflects the intrinsic coercivity classification - later letters in the alphabet indicate higher intrinsic coercivity.

Sintered NdFeB permanent magnets can be classified into seven series based on their intrinsic coercivity (Hcj): N, M, H, SH, UH, EH, and AH (TH). Within each series, specific grades are further subdivided according to the magnet's remanence (Br) and maximum energy product (BH)max.

There are four key parameters to evaluate the magnetic performance of sintered NdFeB products:

1. Br (Remanence)

2. Hcb (Coercivity)

3. Hcj (Intrinsic Coercivity)

4. (BH)max (Maximum Energy Product)

To better understand these concepts, let's use an analogy with heating water:

● Magnetizing a magnet is like heating water

● Br is like the residual heat after stopping heating - it represents the magnet's "magnetic content". For magnets of the same size, higher Br usually means stronger magnetic force

● Demagnetization is like cooling the water:

○ Hcb is like the ambient temperature at which the water's heat is neutralized (no net heat output)

○ Hcj is like the temperature required to completely remove all heat (complete demagnetization)

● Hcb and Hcj are indicators of a magnet's resistance to demagnetization - higher values mean better stability and temperature resistance

Important notes:

● The performance values for each grade are not fixed single values but ranges

● Different manufacturers may have slightly different performance ranges

● Buyers should carefully verify whether a supplier's product meets their requirements

● The data shown represents room temperature (20°C) performance

● Actual working temperature depends on factors like magnet size, coating, etc.

The demagnetization curve (B-H curve) provides a complete characterization of a magnet's performance, including its remanence (Br), coercivity (Hcb), intrinsic coercivity (Hcj), and maximum energy product (BH)max. Most importantly, it reveals the temperature-dependent behavior of these parameters, which is critical for high-temperature applications.

In recent years, leading sintered NdFeB manufacturers have continuously optimized and innovated production processes. Technologies such as heavy rare earth-free formulations, grain boundary diffusion, and cerium-enhanced magnets have seen widespread adoption and development. These advancements have steadily reduced production costs while enhancing the stability and consistency of magnetic properties.