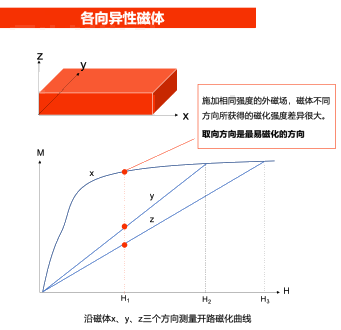

Magnetic materials are classified into two categories: isotropic magnets and anisotropic magnets:

Isotropic magnets exhibit identical magnetic properties in all directions and can be magnetized arbitrarily.

Anisotropic magnets display varying magnetic properties along different orientations. The direction in which they achieve optimal magnetic performance is referred to as the magnet alignment direction.

Common anisotropic magnets primarily include hard magnetic materials such as sintered NdFeB (neodymium iron boron) and sintered SmCo (samarium cobalt).

Alignment is an important process step in the production of sintered NdFeB magnets.

The magnetism of magnets originates from magnetic order (the alignment of magnetic domains in a specific direction). Sintered NdFeB is formed by compacting magnetic powder in a mold. The process involves placing the powder in a mold to form a specific shape, applying a strong magnetic field through electromagnets while simultaneously applying pressure to align the easy magnetization axes of the powder particles uniformly. After pressing, the green compact is demagnetized and then removed from the mold, resulting in a blank with good easy-axis alignment. This blank is later machined into finished magnets according to customer specifications.

Powder alignment is the key process for producing high-performance NdFeB permanent magnets. The quality of alignment during blank production depends on multiple factors, including:

●Alignment magnetic field strength

●Particle morphology and size

●Compaction method

●Relative direction between alignment field and pressing force

●Apparent density of aligned powder

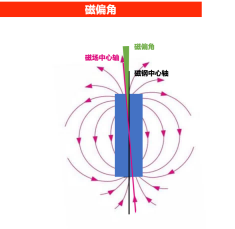

The magnetic deflection angle generated during post-processing has a certain influence on the magnetic field distribution of the magnet.

The magnetic deflection angle refers to the angle between the direction of the magnetic flux lines and the alignment surface of the magnet. The ideal state of the magnetic deflection angle is perpendicular to the alignment surface. However, during post-processing operations such as material bonding and cutting, the cutting direction may form a certain angle with the polar surface due to processing techniques. After subsequent magnetization, the magnetic field strength on the alignment surface will consequently be lower than normal.

The magnetic deflection angle generated during post-processing has a certain influence on the magnetic field distribution of the magnet.

The magnetic deflection angle refers to the angle between the direction of the magnetic flux lines and the alignment surface of the magnet. The ideal state of the magnetic deflection angle is perpendicular to the alignment surface. However, during post-processing operations such as material bonding and cutting, the cutting direction may form a certain angle with the polar surface due to processing techniques. After subsequent magnetization, the magnetic field strength on the alignment surface will consequently be lower than normal.