The magnetic separator is used to separate materials by taking advantage of the magnetic differences among minerals. It plays roles such as improving the grade of ores, purifying solid-liquid materials, and recycling waste, and it is one of the most widely used and highly versatile machine types in the industrial field. Magnetic separators are widely applied in industries such as mining, timber, ceramics, chemistry, and food.

The Structure and Working Principle of Magnetic Separators

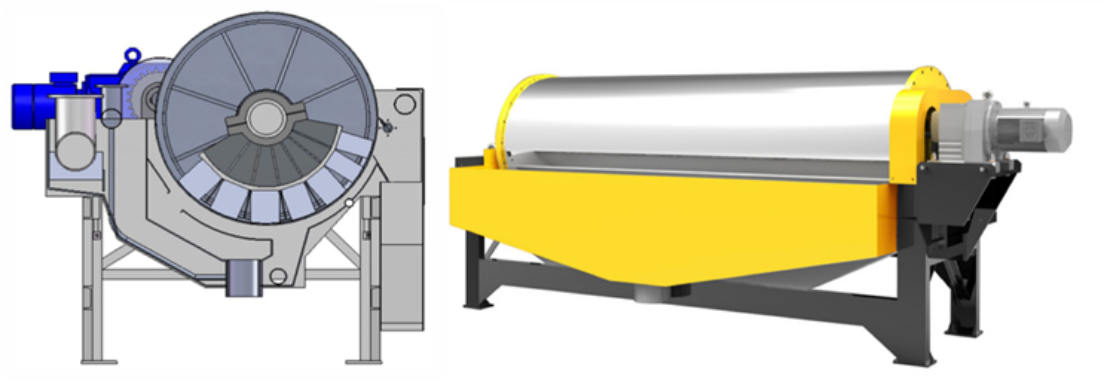

The magnetic separator (taking the wet permanent magnet drum magnetic separator as an example) is mainly composed of six parts: the drum, the roller, the brush roller, the magnetic system, the tank body, and the transmission part. The motor drives the drum, the magnetic roller, and the brush roller to perform a rotary motion through a speed reducer or directly with a stepless speed-regulating motor.

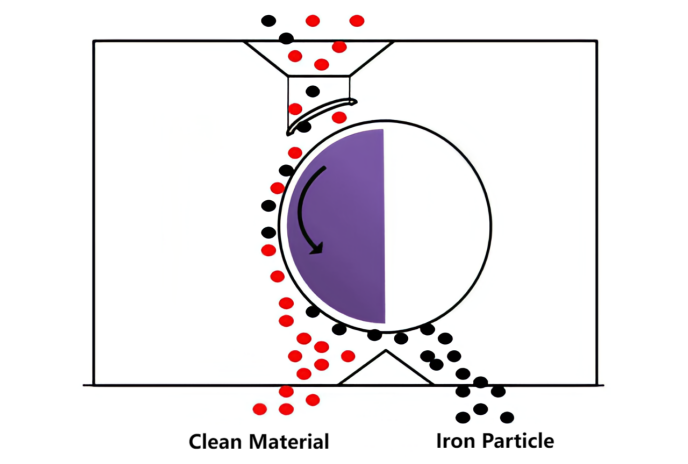

After the ore pulp flows into the tank body through the feeding box, under the action of the water flow from the feeding water spray pipe, the ore particles enter the feeding area of the tank body in a loose state. Under the action of the magnetic field, the magnetic ore particles undergo magnetic aggregation to form "magnetic clusters" or "magnetic chains". The "magnetic clusters" or "magnetic chains" are affected by the magnetic force in the ore pulp and move towards the magnetic poles, and are then adsorbed onto the drum.

Since the polarities of the magnetic poles are alternately arranged along the rotation direction of the drum and remain fixed during operation, when the "magnetic clusters" or "magnetic chains" rotate with the drum, a magnetic stirring phenomenon occurs due to the alternation of the magnetic poles. The gangue and other non-magnetic minerals trapped in the "magnetic clusters" or "magnetic chains" fall off during the tumbling process. Eventually, the "magnetic clusters" or "magnetic chains" adsorbed on the surface of the drum are the concentrate.

The concentrate rotates with the drum to the area where the magnetic force at the edge of the magnetic system is the weakest, and under the action of the flushing water flow ejected from the ore-discharging water pipe, it is discharged into the concentrate tank. The non-magnetic or weakly magnetic minerals are left in the ore pulp and discharged out of the tank with the ore pulp, which is the tailings.

Classification of Magnetic Separators

Magnetic separators can be classified in multiple ways according to different characteristics and standards. Based on the strength of the magnetic field and magnetic force, they can be divided into the following types:

1. Low - intensity magnetic separators: The magnetic field strength on the surface of the magnetic poles is 80-120 kA/m, and the magnetic force is (3-6)×10⁵ kA²/m². They are used for separating strongly magnetic ores.

2. High-intensity magnetic separators: The magnetic field strength on the surface of the magnetic poles is 800 - 1600 kA/m, and the magnetic force is (3-12)×10⁷ kA²/m³. They are used for separating weakly magnetic ores. Based on the separation medium, they can be classified as follows:

(1) Dry magnetic separators: Separation occurs in the air. They are mainly used for separating large-sized, coarse-grained strongly magnetic ores and fine-grained weakly magnetic ores. Currently, efforts are also being made to use them for separating fine - grained strongly magnetic ores.

(2) Wet magnetic separators: Separation takes place in water or magnetic liquids. They are mainly used for separating fine-grained strongly magnetic ores and fine-grained weakly magnetic ores. In addition, magnetic separators can also be classified according to the way magnetic ore particles are separated, the movement direction of the input materials, the method of discharging separation products from the separation area, and the structural characteristics of the discharged magnetic products.

Magnetic Circuit Design and Magnets of Magnetic Separators

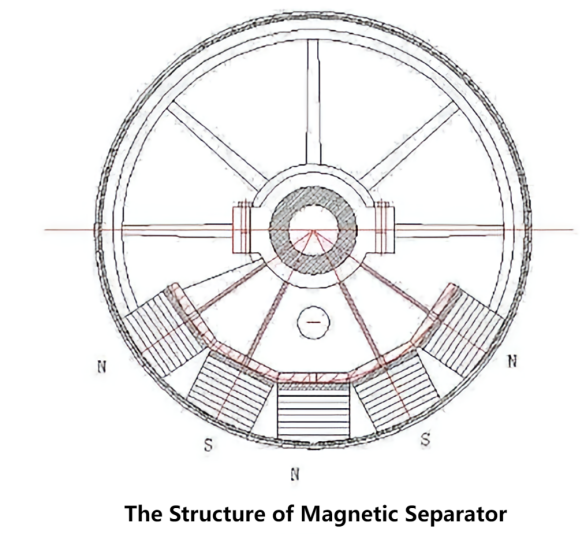

The closed loop through which magnetic flux is concentrated is called a magnetic circuit. The magnetic system of a magnetic separator needs to generate a magnetic field of a certain intensity, and it is required that most of the magnetic flux in the magnetic field can be concentrated through the separation space. Taking the magnetic separator shown in the following figure as an example, the magnetic circuit part uses a five - pole magnetic system.

Each magnetic pole is formed by bonding ferrite and NdFeB permanent magnet blocks. It is fixed on the magnetic conductive plate with screws passing through the center holes of the magnet blocks. The magnetic conductive plate is fixed on the shaft of the cylinder via a bracket. The magnetic system is fixed, while the cylinder can rotate.

The polarities of the magnetic poles are alternately arranged along the circumference and are the same along the axial direction. The drum outside the magnetic system is made of non - magnetic stainless steel. The use of non - magnetic materials is to prevent the magnetic lines of force from being unable to penetrate the cylinder and enter the separation area, thus avoiding forming a magnetic short - circuit with the cylinder. The part of the tank body close to the magnetic system should also be made of non - magnetic materials, while the rest can be made of ordinary steel plates or hard plastic plates.

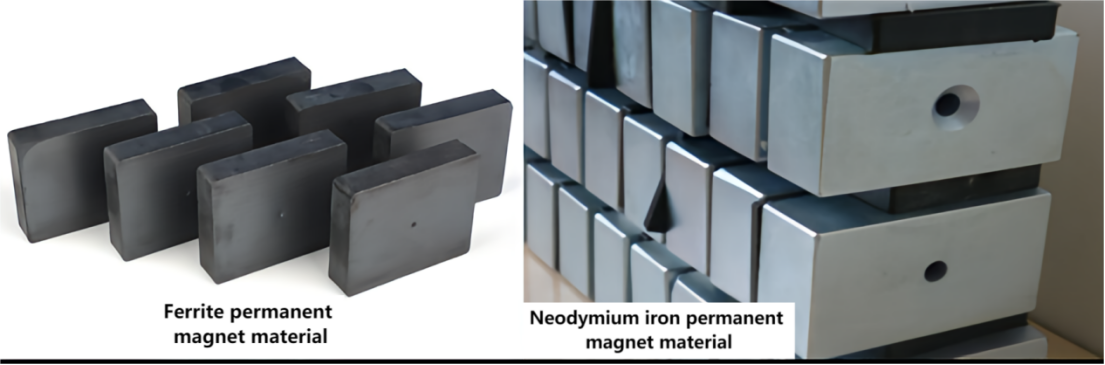

For permanent magnet separators, permanent magnets are the most important components. The quality of permanent magnets determines the performance characteristics of the separators. The permanent magnets of magnetic separators are generally made into certain sizes (for example, length * width * height = 85 * 65 * 18 mm), so they are customarily called permanent magnet blocks or simply magnet blocks. Currently, the mainstream permanent magnet materials used in domestic magnetic separation equipment are mainly permanent magnet ferrites (strontium ferrite and barium ferrite), followed by NdFeB permanent magnet materials.

In the design of the magnetic system, it is necessary to determine which permanent magnet material to use based on various specific circumstances. The influencing factors can be summarized as follows:

1. Magnetic field strength: A constant magnetic field needs to be generated within the specified working space. The strength of this magnetic field determines which permanent magnet material should be used. The magnetic performance of NdFeB permanent magnets is much higher than that of ferrites.

2. Requirement for magnetic field stability: This refers to the influence of environmental factors such as temperature, humidity, vibration, and impact on the permanent magnet material and its adaptability to these factors.

3. Mechanical properties: Such as the toughness, flexibility, and compressive strength of the magnet.

4. Cost: The price of the permanent magnet material also plays a role in the decision - making process.