Sintered NdFeB permanent magnets, as core functional components, are widely used in instruments and equipment such as motors, electroacoustics, magnetic suction devices, and sensors. During their service life, the magnets are subjected to environmental factors such as mechanical forces, thermal changes, and alternating electromagnetic fields. If environmental failure occurs, it will seriously affect the functionality of the equipment and cause huge losses. Therefore, in addition to magnetic performance indicators, we also need to pay attention to the mechanical, thermal, and electrical properties of the magnets. This will help us better design and use the magnetic steel, and is of great significance for improving its service stability and reliability.

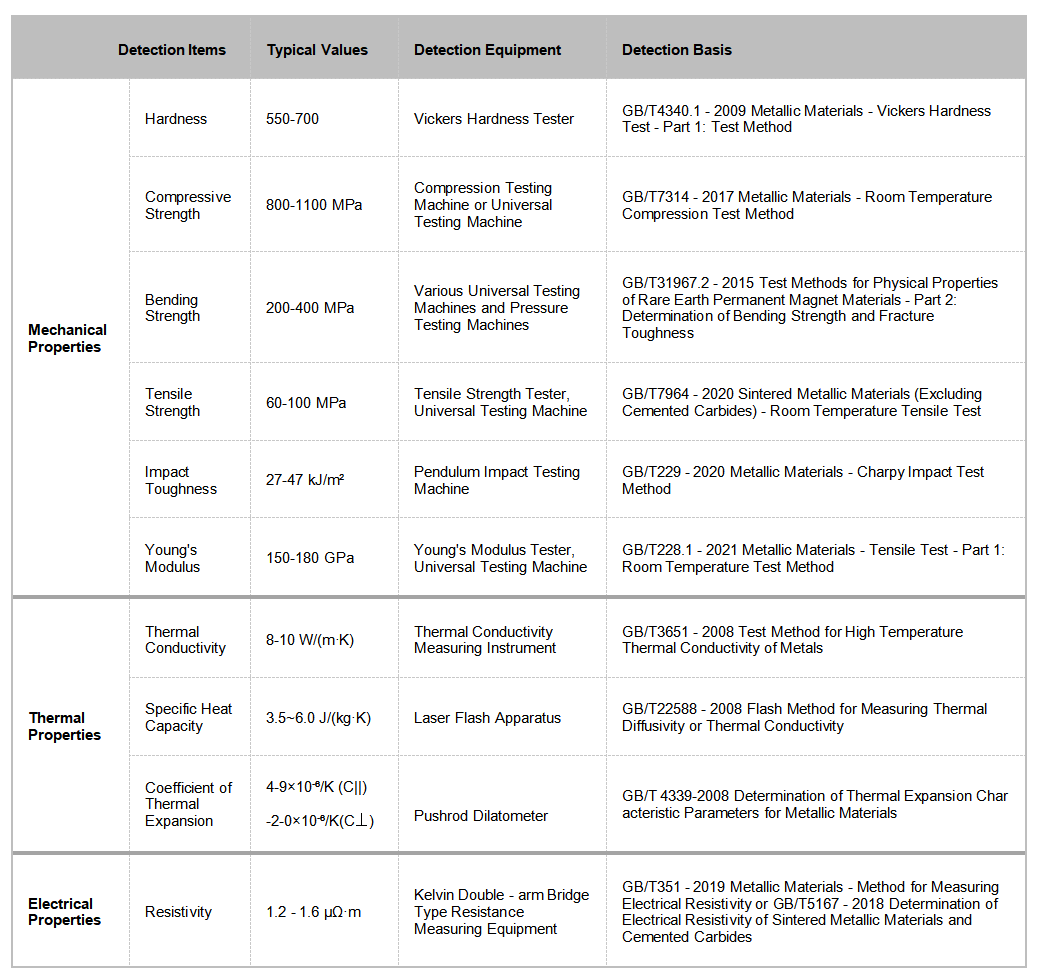

Mechanical Properties

The mechanical property indicators of magnetic steel include hardness, compressive strength, flexural strength, tensile strength, impact toughness, Young's modulus, etc. NdFeB is a typical brittle material: it has high hardness and compressive strength, but poor flexural strength, tensile strength, and impact toughness. This makes the magnetic steel prone to chipping or even cracking during processing, magnetization, and assembly. Magnetic steel in components and equipment is usually fixed by clamping grooves or adhesive bonding, while shock absorption and buffer protection should be ensured. The fracture surface of sintered NdFeB is typically intergranular fracture, and its mechanical properties are mainly determined by its complex multiphase structure, as well as related to formula composition, process parameters, and structural defects (pores, large grains, dislocations, etc.). Generally, the lower the total rare earth content, the worse the mechanical properties of the material. Adding appropriate amounts of low-melting-point metals such as Cu and Ga to improve the distribution of grain boundary phases can enhance the toughness of magnetic steel. Adding high-melting-point metals such as Zr, Nb, and Ti can form precipitation phases at grain boundaries, refine grains, and inhibit crack propagation, helping to improve strength and toughness. However, excessive addition of high-melting-point metals will lead to excessively high hardness of magnetic materials, seriously affecting processing efficiency. In actual production, the magnetic properties and mechanical properties of magnetic materials are difficult to balance. Limited by cost and performance requirements, the processability and assemblability are often sacrificed.

Thermal Properties

The main thermal property indicators of NdFeB magnetic steel include thermal conductivity, specific heat capacity, and thermal expansion coefficient.

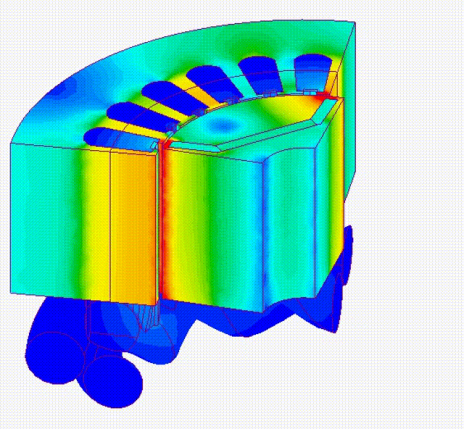

Simulation of Magnetic Steel Status during Motor Operation

The performance of magnetic steel gradually deteriorates as temperature increases, so the temperature rise of permanent magnet motors becomes a critical factor determining whether the motor can operate under long-term load. Only with good thermal conductivity and heat dissipation capacity can overheating be avoided to maintain normal equipment operation. Therefore, it is expected that magnetic steel has high thermal conductivity and specific heat capacity: on one hand, heat can be quickly conducted and dissipated, and on the other hand, the same amount of heat causes lower temperature rise. NdFeB magnetic steel is prone to magnetization in a specific direction (∥C-axis), and the magnetic steel expands when heated in this direction; however, negative expansion occurs in the two difficult magnetization directions (⊥C-axis), meaning contraction upon heating. The anisotropy of thermal expansion leads to easy cracking of radial ring magnetic steel during the sintering process. In permanent magnet motors, frames made of soft magnetic materials are mostly used to support the magnetic steel, and the different thermal expansion characteristics of the two materials will affect the dimensional compatibility after temperature rise.

Electrical Properties

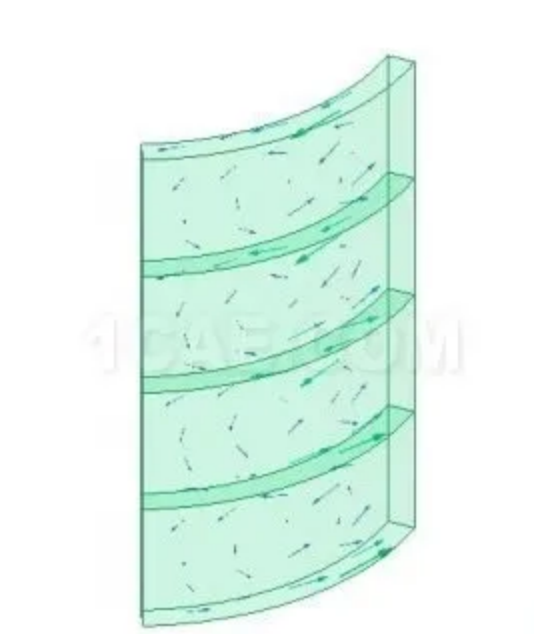

Eddy Currents in Magnetic Steel under Alternating Fields

In the alternating electromagnetic field of a rotating permanent magnet motor, eddy current losses occur in the magnetic steel, causing temperature rise. Since eddy current loss is inversely proportional to resistivity, increasing the resistivity of NdFeB permanent magnets can effectively reduce eddy current losses and temperature rise in the magnetic steel. The ideal high-resistivity magnetic steel structure increases the electrode potential of rare earth-rich phases to form isolation layers that block electron transmission, achieving encapsulation and separation of main-phase grains by high-resistance grain boundary phases to improve the resistivity of sintered NdFeB magnets. However, neither inorganic material doping nor lamination technology can solve the problem of magnetic performance degradation. At present, there is still no effective method to prepare magnets with both high resistivity and high performance.