Based on the basic performance requirements of new energy vehicle drive motors, the current commonly used drive motor types mainly include three categories, namely AC asynchronous motors, permanent magnet synchronous motors and switched reluctance motors. At present, in the statistics of supporting models of various automobile enterprises, the type of drive motor selected for each model is also different.

Therefore, to carry out the new energy vehicle mounted motor type selection, it is very important to understand the structure, working principle and performance advantages and disadvantages of the drive motor.

AC Asynchronous Motor

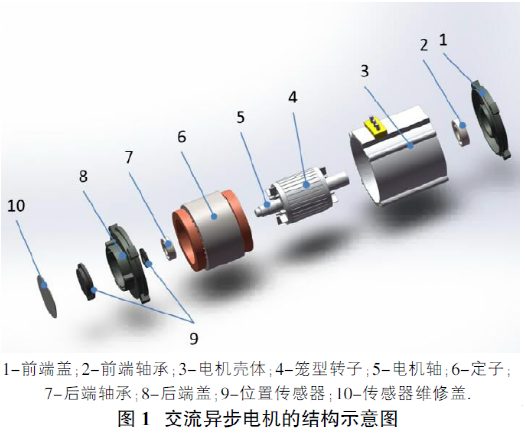

1. Structure of AC asynchronous motor

The structure of AC asynchronous motor, also known as induction motor, mainly includes stator, rotor, motor shaft, front and rear bearings, end cover, position sensor, temperature sensor, low-voltage wiring harness and high-voltage power harness. The stator consists of a stator core and three-phase windings; the rotor is commonly used as a cage rotor, including the rotor core and cage windings. Depending on the power of the motor will choose water-cooled or air-cooled mode. (Figure 1)

2. The working principle of AC asynchronous motor

(1) Working principle of AC asynchronous motor drive

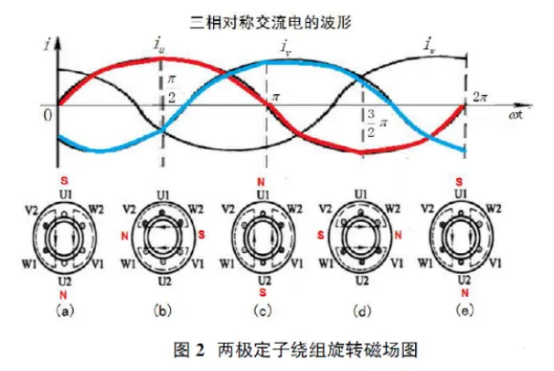

(1) The stator provides a rotating magnetic field. To drive an AC asynchronous motor to provide torque, a three-phase alternating current needs to be passed through the stator coils to produce a constantly rotating magnetic field (the magnetic field rotates at ns). AC asynchronous motor requirements stator three-phase winding must be symmetrical, and stator core space on the difference between each other 120 degrees of electrical angle; through the three-phase symmetrical winding current must also be symmetrical, size, frequency, phase difference of 120 degrees. The rotational speed of the rotating magnetic field, see equation (1).

ns = 60f / p (1)

Where, ns for the rotating magnetic field speed (also known as synchronous speed), r/min; f for the three-phase alternating current frequency, Hz; p for the number of magnetic poles. For the drive motor that has been designed and finalized for production, the number of magnetic stage pairs has been determined, so the factor that determines the rotational speed of the magnetic field is the three-phase alternating current frequency. Since our power grid frequency f = 50Hz, the motor speed and the number of magnetic pole pairs have a linear relationship. (Figure 2

)![]()

![]()

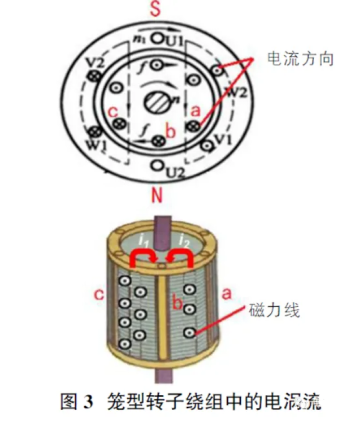

2) Cage rotor provides induced eddy currents. Due to the rotating magnetic field provided by the stator, eddy currents are induced on the cage rotor conductor as shown in Fig. 3. In the magnetically conductive region between the cage winding conductors c and b, there is an outwardly directed line of magnetic force and this line of magnetic force is enhanced by the rotating magnetic field, so that i1 eddy currents are induced on the conductors c and b. Similarly, the weakened line of magnetic force in the region of the conductor a and conductor b induces i2 eddy currents on the conductors. The current on conductor b, under the action of the rotating magnetic field of the stator, causes an electromagnetic force to be applied to conductor b of the cage winding, which causes the rotor to rotate by generating an electromagnetic torque. The rotating rotor gradually catches up with the rotating magnetic field and rotates at a speed n slightly slower than the “synchronous speed ns” of the magnetic field. This phenomenon of the rotor rotating at a speed n slightly slower than the speed ns of the stator magnetic field is known as rotor rotation, and this asynchronous rotation allows the cage rotor conductor to continue to cut the magnetic lines of force to produce induced eddy currents, and thus, in the rotor, electrical energy is converted into mechanical energy to ensure a continuous output to the outside world.

![]()

(2) Principle of operation of AC asynchronous motor for power generation

According to Faraday's Law of Electromagnetic Induction, when a part of a closed circuit conductor cuts the motion of magnetic induction in a magnetic field, an induced current is generated in the conductor, and the resulting electromotive force becomes the induced electromotive force. In the AC asynchronous motor, the motor as a generator, the stator in the through three-phase current for the excitation current, to provide a magnetic field, the rotor windings to provide a conductor, when through external mechanical force, such as automobile drive shaft drives the rotor shaft, thus driving the rotor movement, if the rotor on the rotor is higher than the synchronous rotational speed of the rotating magnetic field of the stator, at this time the AC asynchronous motor that is the generator, the rotor is at this time to cut the rotating magnetic field of the The direction of the rotor cutting the rotating magnetic field at this time is opposite to that of the rotor working as a drive motor, and thus the direction of the induced electromotive force of the rotor is also opposite. In the process of power generation, the motor rotor is subjected to electromagnetic resistance torque opposite to the external drag force, so that the rotor speed decreases.

3. Advantages, disadvantages and application scope of AC asynchronous motor

The advantage of AC asynchronous motor is that the output torque can be adjusted in a wide range, and it can be forced to increase the output torque in a short period of time when accelerating or climbing a slope, and the electric-driven cars with permanent magnet synchronous motor usually increase the torque by adding a gearbox mechanism to increase the speed. But the disadvantage of AC asynchronous motor is that the motor due to unilateral excitation, the start-up current is larger, the current required to produce unit torque is larger, and there is a reactive excitation current in the stator, so the energy consumption is larger than the permanent magnet synchronous motor, the power factor lag; heavy-duty drive is often overload phenomenon; the structure is relatively complex, and its control technology requirements are high, the high cost of manufacturing; the power density is relatively low. At present, the United States developed the electric drive vehicles mostly use AC asynchronous motor as the drive motor.

Permanent magnet synchronous motor

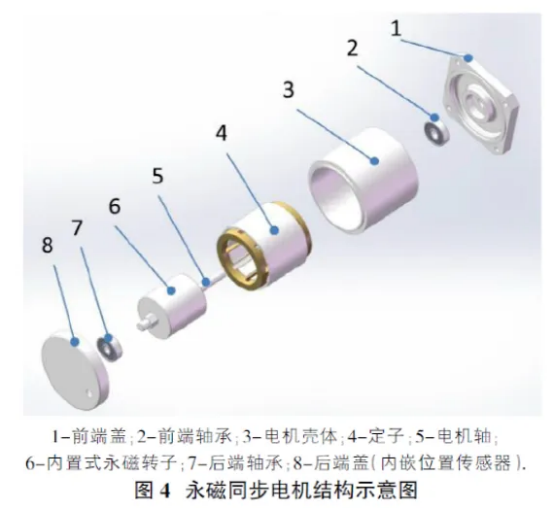

1. Structure of permanent magnet synchronous motor

The structure of permanent magnet synchronous motor includes stator, rotor, motor shaft, front and rear bearings, end cover, cooling waterway, position sensor, temperature sensor, low-voltage wiring harness and power wiring harness. The stator consists of a stator core and three-phase windings; the rotor consists of permanent magnet poles and a core, which is stacked with silicon steel sheets. According to the arrangement of permanent magnets in the rotor, it mainly includes surface protruding permanent magnet rotor, surface embedded permanent magnet rotor and built-in permanent magnet rotor, and the built-in permanent magnet rotor is commonly used in new energy motors at present. (Figure 4)

![]()

2. Working principle of permanent magnet synchronous motor

(1) Working principle of permanent magnet synchronous motor drive

The rotating magnetic field is provided by the stator, and the magnetic field is generated in the same way and at the same speed as that of the AC asynchronous motor. The magnetic poles are provided by the rotor permanent magnets. In this way, the rotating magnetic field generated by the stator forms a circuit with the magnetic poles of the rotor permanent magnets and the rotor core. According to the principle of minimum reluctance, that is, the magnetic flux is always closed along the path of minimum reluctance, the electromagnetic force of the rotating magnetic field is used to pull the rotor to rotate, so the permanent magnet rotor will follow the rotating magnetic field generated by the stator to rotate synchronously, thus driving the motor shaft to rotate.

(2) Power generation principle of permanent magnet synchronous motor

According to Faraday's law of electromagnetic induction, part of the conductor of the closed circuit is provided by the three-phase stator winding, the magnetic field is provided by the permanent magnets on the rotor, when the external torque drives the rotor to rotate, generating a rotating magnetic field, cutting the three-phase stator winding in part of the conductor, resulting in induction of the three-phase symmetric current, at this time, the rotor's kinetic energy is converted into electrical energy, permanent magnet synchronous motor as a generator work.

3. Advantages and disadvantages of permanent magnet synchronous motor and application scope

The advantages of permanent magnet synchronous motors are small size, light weight, high power density, low energy consumption compared to asynchronous motors, low temperature rise and high efficiency. It can be designed as a structured motor with high starting torque and high overload capacity according to the demand. Permanent magnet synchronous motor strictly synchronized, dynamic response performance is better, suitable for frequency control, adjust the current and frequency can be adjusted to a wide range of motor torque and speed. However, the permanent magnet material in the permanent magnet synchronous motor usually adopts neodymium iron boron strong magnetic material, which is brittle and hard, and may be broken by strong vibration; and the rotor adopts the permanent magnet material, which will have magnetic recession in the use of the motor and over-temperature, resulting in a decline in power. Currently, permanent magnet synchronous motors are widely used in new energy vehicle motors, and the new energy markets in Asia and Europe mainly use permanent magnet synchronous motors as new energy motors.

Switched Reluctance Motor

1.Structure of switched reluctance motor

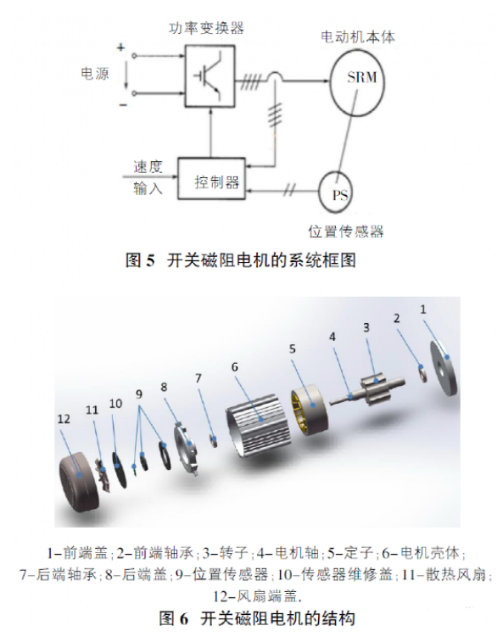

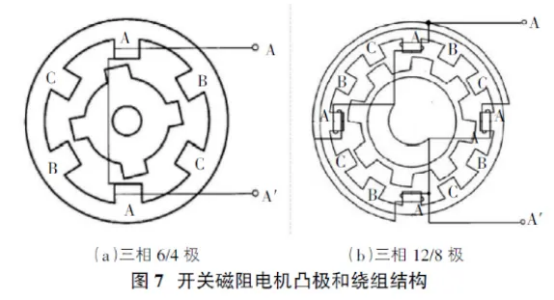

Switched reluctance motor is a typical mechatronic motor, also known as “switched reluctance motor drive system”, which mainly includes four parts: switched reluctance motor body, power converter, rotor position sensor and controller, as shown in Figure 5. The main structure of switched reluctance motor body includes stator, rotor, position sensor, front and rear bearings, front and rear end caps and motor case, etc., as shown in Figure 6. Among them, the stator includes stator core and winding. The stator core and rotor are both of convex pole structure, and the stator convex pole core and rotor are both made of silicon steel sheets stacked together, and the windings are arranged on the stator convex pole, and the rotor has no windings and permanent magnets.

![]()

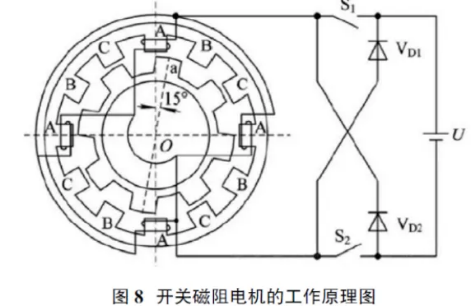

The three-phase 6/4-pole structure indicates that the motor has 6 convex poles in the stator and a convex pole in the rotor, in which the centralized windings on the two symmetrical convex poles of the stator are connected in series with each other, constituting one phase, and the number of phases is the number of convex poles of the stator/2, as shown in Fig. 7(a). The three-phase 12/8-pole structure indicates that the motor has 12 convex poles in the stator and 8 convex poles in the rotor, in which the windings on the 4 two symmetrical convex poles of the stator are connected in series with each other to form a phase, and the number of phases is the number of convex poles of the stator/4 as shown in Fig. 7(b).

Switched reluctance motor more phases, the smaller the step angle, the smoother the operation, the more conducive to reducing torque fluctuations, but the more complex the control, so that the main switching devices to increase and increase the cost.

Calculation of the stepping angle, see equation (2):

α = 360° × (number of stator poles - number of rotor poles) / (number of stator poles) (2) such as three-phase 6/4-pole motor, its stepping angle a = 360 ° × 2 (/ 6 × 4) = 30 °.

![]()

2. Working principle of switched reluctance motor

(1) Driving principle of switched reluctance motor

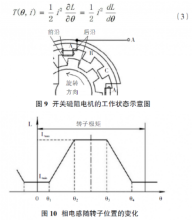

As can be seen from the three-phase 12/8-pole switched reluctance motor operating principle diagram in Figure 8, when the A-phase winding current control main switch S1, S2 closed, A-phase energized excitation, the magnetic field generated in the motor force to OA as the axis of the radial magnetic field, the magnetic field magnetic line of force in the stator pole and rotor pole through the stator pole and rotor pole of the air gap is curved, at this time, the magnetic resistance of the magnetic circuit is greater than that of the stator pole and the rotor pole when the stator pole and rotor pole overlap, and the rotor pole is subjected to the action of magnetic field pulling force, so the rotor pole axis Oa and stator pole axis Oa, the rotor pole axis Oa, the rotor pole axis Oa. Therefore, the rotor pole is subjected to the action of the magnetic field pulling force, so that the rotor pole axis Oa and stator pole axis OA coincide, thus generating electromagnetic torque of the nature of the magnetoresistance, so that the rotor rotates counterclockwise. Turn off the A-phase power and establish the B-phase power supply, then at this time the magnetic field inside the motor rotates 30 degrees, then the rotor rotates 15 degrees counterclockwise continuously under the action of electromagnetic tension at this time. If the sequence to the A-B-C-A phase winding energized, the rotor will rotate continuously in the counterclockwise direction; when the stator winding in each phase is energized once in turn, the stator magnetic field rotates through 3 × 30 degrees, and the rotor rotates through a rotor pole distance of 3 × 15 degrees (i.e., 360 degrees/number of rotor convex poles). If the A-C-B-A phase windings are energized in sequence, the rotor will turn in a clockwise direction. Switched reluctance motors are independent of the direction of current and depend on the order in which the stator phase windings are energized. In the actual operation of multiphase motors, it is also common for two or more phase windings to be energized at the same time.

![]()

(2) Generation principle of switched reluctance motor

The switched reluctance generator operating state phase inductance exists in three states, the excitation state, the continuation state and the power generation state, and its phase inductance L waveform is shown in Fig. 10.

In Fig. 9, the angle θ is defined as the angle between the rotor tooth pole axis and the stator tooth slot axis for that phase. When the rotor tooth pole axis coincides with the corresponding stator tooth slot axis, this phase inductance is the smallest (defined as θ = 0°); until the front edge of the rotor convex pole meets the back edge of the stator convex pole (θ = θ1), the winding phase inductance is always Lmin constant; when the rotor continues to rotate, the rotor convex pole begins to appear to coincide with the stator convex pole until the back edge of the rotor convex pole and the back edge of the stator convex pole are completely coincident (at this time, θ = θ2) The phase inductance of the winding rises linearly in this region until the maximum value Lmax; when the rotor continues to rotate until the front edge of the rotor convex pole and the front edge of the stator convex pole coincide, at this time θ = θ4, and the phase inductance continues to Lmax.

According to the basic theory of electromagnetic field, along with the existence of magnetic field, the electromagnetic torque of the motor rotor exists at the same time, which can be expressed as equation (3).

If the windings of a switched reluctance motor are turned on and off between θ3 and θ4, the motor operates as a generator machine. At this time, the current is formed in the inductance drop area, then dL/dθ<0, at this time the phase winding has current through, then the braking torque is generated (T (θ, i)<0), if the external mechanical force to maintain the motor rotation, then the motor absorbs the mechanical energy and converts it into electrical energy output, at this time the switched reluctance motor is a generator mode of operation.

3. Advantages and disadvantages of switched reluctance motor and application scope

The advantages of switched reluctance motor are simple and reliable structure, good starting performance, high efficiency, low cost, can change the conduction, off angle and voltage to speed regulation, has a wide range of speed regulation and ability. The disadvantages of switched reluctance motor are large torque pulsation and high noise. It is currently used in some small electric-driven vehicles, such as electric-driven four-wheeled mobility scooters and patrol cars.

According to the requirements of the new energy vehicle drive motor's own performance characteristics, the drive motors selected for the current market models are different. The paper describes the structure and working principle of AC asynchronous motors, permanent magnet synchronous motors and switched reluctance motors, which are currently commonly used as new energy drive motors, and will help to better understand the drive motors.

Moreover, due to the different structures and principles of each type of motor, the scope of application is quite different. According to the country's industrial strategic planning, research in the direction of electric drive systems for environmentally friendly new energy vehicles will become more and more extensive, and the types of motors and technology levels will continue to improve.