Both samarium-cobalt (SmCo) and neodymium-iron-boron (NdFeB) are metallic materials. Due to the good electrical conductivity of metallic materials, their electrical resistivity is very low. This is not beneficial for rotating machinery such as motors, as it leads to eddy current loss in the rotating machinery, causing heating of the rotating machinery including the magnets. Therefore, eddy current loss in magnets occurring in rotating machinery must be considered by magnet and motor designers.

Today, Rano will take you to understand what magnet eddy current loss is and how to avoid it in the production of magnetic materials.

To understand and reduce eddy current loss, we first need to know how it is generated. This requires introducing a concept—the skin effect.

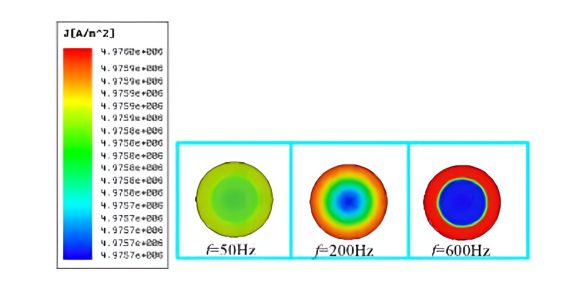

When an alternating current passes through a conductor, the current density is unevenly distributed across the cross-section of the conductor. As the frequency of the current changes increases, the current becomes more and more concentrated on the surface of the conductor, while the current inside the conductor becomes smaller and smaller. This phenomenon is called the skin effect.

- The higher the frequency, the stronger the skin effect.

The cause of the skin effect is precisely eddy currents. According to Faraday’s Law of Electromagnetic Induction, an alternating electric field generates an alternating magnetic field around it. When alternating current passes through a conductor, it creates an alternating magnetic field both inside and around the conductor, inducing spiral-shaped induced currents inside the conductor—these are referred to as eddy currents for short.

The closer to the center of the conductor, the higher the induced electromotive force generated by the alternating magnetic field inside the conductor, and the stronger the eddy currents. This results in a stronger opposing effect on the original current, leading to a lower current density near the center of the conductor and a higher current density near the surface.

Since the induced electromotive force increases with the increase in frequency, the skin effect also becomes more significant as the frequency rises. When a very high-frequency current passes through a conductor, it can be assumed that the current only flows through a very thin layer on the conductor’s surface. This is equivalent to a reduction in the cross-sectional area of the conductor, greatly lowering the effective utilization rate of the conductor material.

Eddy Current Loss

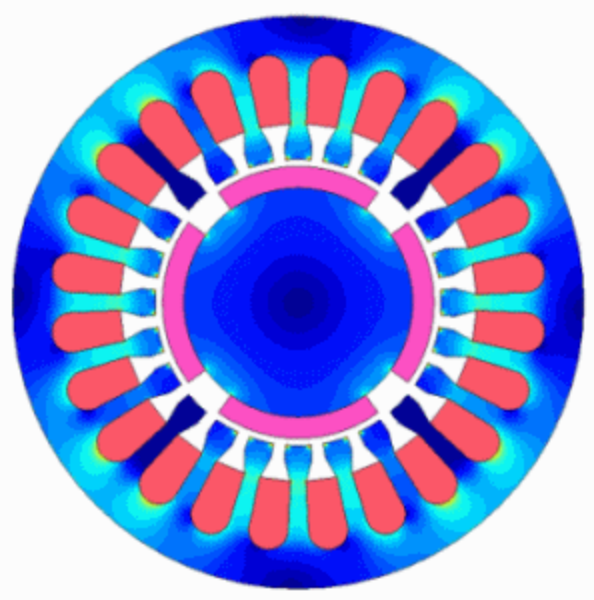

Due to the relatively low electrical resistivity of SmCo and NdFeB permanent magnets, the eddy currents in these magnets under alternating electric fields are generally relatively large. Due to the Joule heating effect of current, eddy currents cause the magnets to heat up. If the temperature is too high, thermal demagnetization will occur.

The magnitude of eddy current loss is related to factors such as the variation mode of the magnetic field, the movement of the magnet, the shape of the magnet, magnetic permeability, and electrical resistivity. For rotating machinery:

- The higher the rotational speed (equivalent to frequency) and magnetic permeability,

- The lower the electrical resistivity,

The smaller the skin depth, and the greater the resulting loss. In fields such as electric vehicles and elevators, permanent magnet motors are usually controlled by inverter power sources for speed regulation. The presence of high-order harmonics in the carrier frequency also increases eddy current loss in the magnets and causes thermal demagnetization.

Reducing Eddy Current Loss in Sintered NdFeB by Increasing Electrical Resistivity

From the perspective of motor design, several technical methods have been proposed to reduce eddy current loss of permanent magnets in rotating machinery, such as using shielding columns around the magnets, segmenting the magnets, and isolating the sides of the magnets.

From the perspective of magnet manufacturing, one of the most effective methods to reduce eddy current loss in motors is to use bonded magnets. Due to the presence of binders and their sufficiently high volume fraction, the electrical resistivity of bonded magnets is 10² to 10⁴ times that of sintered magnets. However, this method greatly limits the power and maximum operating temperature of the motor. Therefore, the most direct method is to **increase the electrical resistivity of sintered magnets themselves.

There are multiple ways to increase the electrical resistivity of sintered magnets, such as adding high-resistivity powders (e.g., Al₂O₃) and coating the magnets with SiO₂. However, these methods will all affect the magnetic properties of the sintered magnets to a certain extent. Therefore, during the magnet R&D process, a balance must be struck between electrical resistivity and magnetic properties.