NdFeB materials have two distinctive features, one is that they can be strongly magnetized under the action of an external magnetic field, and the other is hysteresis, i.e., the hard magnetic material retains its magnetized state after the external magnetic field is withdrawn. So how do you demagnetize a magnet that has been magnetized to a technically saturated state? Today we will learn about the principles and methods of demagnetization. Demagnetization (demagnetization), also known as magnetic cleaning (magnetic cleaning), demagnetization, etc., is the process of restoring a magnet to a magnetically neutral state, also known as magnetic neutralization. There are three methods of demagnetization in industrial processing:

1、Static demagnetization

Add a magnetic field in the opposite direction to the original magnetization of the magnet, the strength of this anti-magnetic field should ensure that when it is withdrawn, exactly so that the magnetic induction of the magnet becomes zero. The resulting magnetic neutral state is called the static magnetic neutral state.

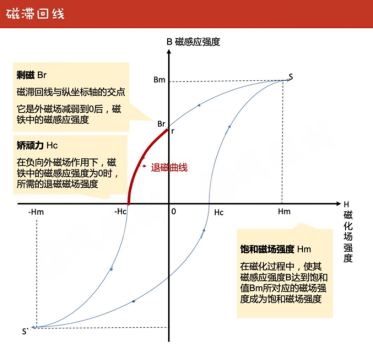

In the hysteresis curve, the red line segment in the second quadrant represents the demagnetization curve, i.e., when the magnet is subjected to a magnetic field in the opposite direction to the magnetizing direction, its magnetic induction decreases with the increase of the strength of the reverse magnetizing field, and when the strength of this reverse magnetizing field reaches -Hc, the magnet's magnetic induction decreases to 0, and at that time, the magnet no longer has magnetic properties.

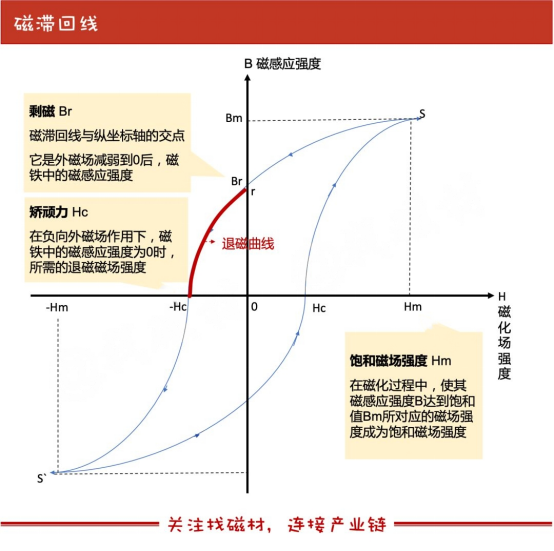

The hysteresis line is measured at room temperature, and the demagnetization curve is not the same when the magnet is operated at different temperatures, as shown in the figure below. Therefore, the strength of the reverse magnetic field applied for demagnetization at different temperatures is different.

(Image from the Internet)

2、Dynamic demagnetization

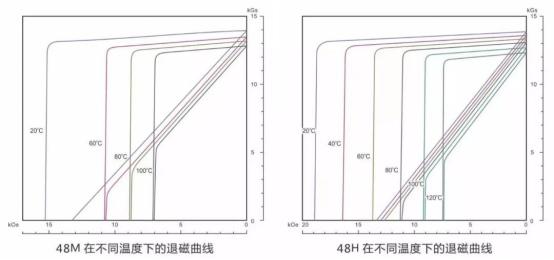

A sufficiently strong alternating magnetic field is applied to a magnetic body, and then the amplitude of the alternating field is gradually reduced to 0. The resulting magnetic neutral state is called the dynamic magnetic neutral state.

The principle of this method is to place the workpiece in the alternating magnetic field, and use the hysteresis line decreasing demagnetization. As the amplitude of the alternating magnetic field gradually decays, the trajectory of the hysteresis loop becomes smaller and smaller. When the magnetic field gradually attenuates to zero, the residual magnetism in the workpiece will be close to zero, the principle of demagnetization is shown in the figure below. It can be seen that the demagnetization of the current and magnetic field direction and size of the change must be reversed and attenuation at the same time.

A sufficiently strong alternating magnetic field is applied to a magnetic body, and then the amplitude of the alternating field is gradually reduced to 0. The resulting magnetically neutral state is called the dynamic magnetically neutral state.

The principle of this method is to place the workpiece in an alternating magnetic field and demagnetize it by using a decreasing hysteresis loop. As the amplitude of the alternating magnetic field gradually decays, the trajectory of the hysteresis loop becomes smaller and smaller. When the magnetic field gradually attenuates to zero, the residual magnetism in the workpiece will be close to zero, the principle of demagnetization is shown in the figure below. It can be seen that the demagnetization of the current and magnetic field direction and size of the change must be reversed and attenuation at the same time.

(1) Alternating current demagnetization

To demagnetize workpieces magnetized by alternating current (AC), either the pass-through method or the attenuation method can be used.

A Pass-through method

For batch demagnetization of small and medium-sized workpieces, it is better to put the workpieces on the demagnetizing machine equipped with tracks and drag boards. When demagnetizing, put the workpieces on the drag boards and place them in front of the coils at 30cm, and when the coils are energized, pass the workpieces from the coils along the tracks and away from the coils slowly and cut off the power at least 1m away from the coils. For heavy or large workpieces that cannot be demagnetized on the demagnetizer, the coil can also be placed on the workpiece, and when the coil is energized, the workpiece is slowly passed through the coil and de-energized at least 1m away from the workpiece.

(Demagnetizer, image from the web)

B Attenuation Method

Because the direction of the alternating current is constantly changing, so we can use automatic attenuation demagnetizer or voltage regulator to gradually reduce the current to zero for demagnetization, put the workpiece in the coil, clamped between the two magnetizing chucks of the flaw detector, or contact the workpiece with the support rod contact to reduce the current to zero for demagnetization.

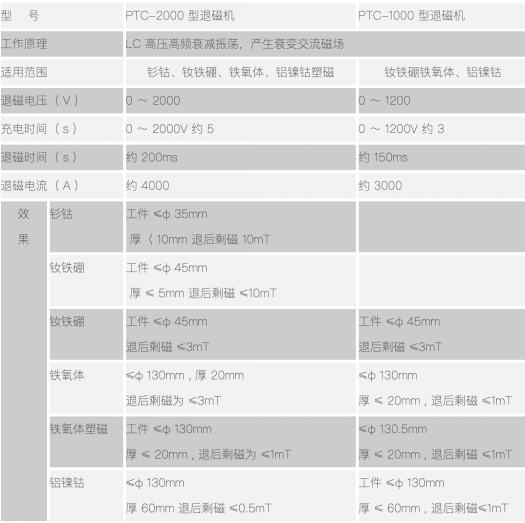

The picture below shows the demagnetization effect of a demagnetizer found on the internet by Magnetron, you can see that after demagnetization, there is still some residual magnetism in the magnet. The price of the demagnetizer is mainly related to the capacity of the storage capacitor, the charging voltage (demagnetizer energy), when purchasing a demagnetizer, you should mainly consider the grade of the demagnetized product or the endowment coercivity and demagnetized sample size and other factors.

(Performance of a special demagnetizer for magnetic materials, picture from the Internet)

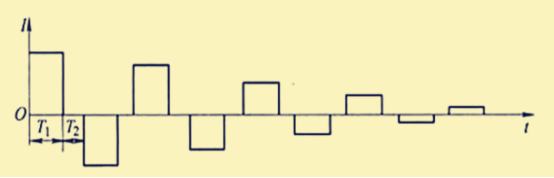

(2) Direct current demagnetization

Demagnetization is carried out by continuously changing the direction of the DC current while the current through the workpiece decreases to zero. DC demagnetization current waveform is shown in the figure below, where T1 is the current conduction time interval, T2 is the current disconnection time interval, to ensure that the current changes direction at the time of disconnection. Current decay should be as many times as possible (generally require more than 30 times), each attenuation of the current amplitude should be as small as possible, if the amplitude of the attenuation is too large, the purpose of demagnetization can not be achieved.

3、Thermal demagnetization

Thermal demagnetization is a way to heat the magnetic body to above Curie temperature and then cool it without external magnetic field. Sintered NdFeB can be thermally demagnetized by baking at a high temperature above 350℃ for about 30 minutes to 1 hour.

Within the working temperature, the magnetic force of the magnet will drop when the temperature rises, but most of the magnetic force will be restored after cooling. If the temperature reaches the Curie temperature, the molecules inside the magnet move violently and demagnetization occurs, and this demagnetization is irreversible.

Regardless of which of the above three ways to demagnetize a magnet, the internal structure of the magnet will be permanently altered, and after demagnetization and then magnetization of the magnet, the magnetic properties can not be restored to the previous level.