The cerium (Ce) element exhibits variable valence states and a relatively small ionic radius. When Ce content is high, it tends to form CeFe₂ phases, which makes it challenging to achieve high coercivity in the magnets. Due to the low saturation magnetization and anisotropy field of CeFeB alloys, diffusion process treatment is typically required after Ce addition to further enhance the performance of Ce-containing magnets.

When the Ce addition is minimal, its impact on diffusion performance is negligible. However, with higher Ce content—particularly exceeding 12%—the magnet's microstructure deteriorates significantly. This not only substantially diminishes the enhancement effect of diffusion treatment but also leads to degraded squareness of the demagnetization curve due to microstructural inhomogeneity.

From an application perspective, when the Ce content in the base material is low, Ce-containing magnets demonstrate comparable magnetic moment and high-temperature demagnetization behavior to Ce-free magnets at equivalent Br and Hcj levels, exhibiting essentially identical performance characteristics. However, with Ce content exceeding 8% (particularly above 12%), special attention must be paid to two critical issues arising from simultaneously reduced Hcj and squareness:

Incomplete magnetization saturation (leading to sufficient remanence but inadequate magnetic moment)

Accelerated thermal demagnetization (resulting in meeting coercivity specs but insufficient thermal stability)

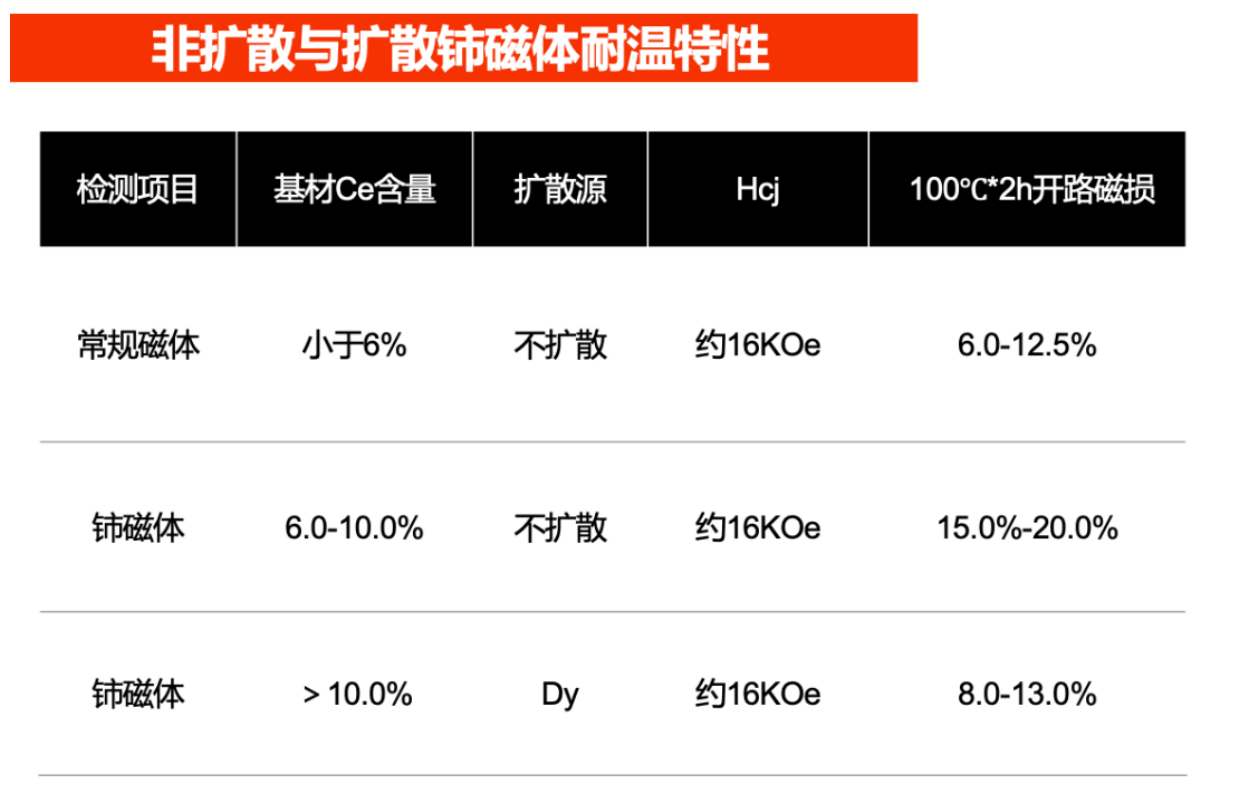

There are notable differences in temperature resistance between conventionally processed Ce-magnets and those treated with diffusion processes. Taking 38MT grade magnets (30×15×3.2mm dimensions) as an example:

Compared to conventional diffusion-treated magnets, Ce-added magnets exhibit progressive deterioration in mechanical properties during processing and application as Ce content increases. This degradation primarily stems from excessive CeFe₂ phase formation, which severely disrupts grain boundary wetting and coupling effects with the main phase grains. Experimental data confirms that when Ce addition exceeds 10%, mechanical properties decline by 20-50%. Affected parameters include hardness, compressive strength, flexural strength, tensile strength, impact toughness, and Young's modulus. Such deterioration exacerbates the inherent brittleness of NdFeB magnets, significantly increasing risks of edge chipping or cracking during machining, magnetization, and assembly processes.

Conclusion & Recommendations for High-Ce Magnet Applications:

In summary, special caution must be exercised when utilizing ultra-high Ce-content magnets due to the following inherent challenges:

1.Suboptimal diffusion efficacy (reduced Hcj improvement post-treatment)

2.Microstructural inhomogeneity (localized weak magnetic zones)

3.Elevated thermal demagnetization risk (lower flux retention at T≥80°C)

4.Degraded mechanical properties (20-50% lower fracture toughness vs. standard grades)

However, with ongoing process advancements, the industry is progressively addressing CeFe₂-related limitations through:

Grain boundary engineering (e.g., Tb/Dy localized diffusion)

Phase distribution optimization (CeFe₂ volume fraction<3% in next-gen alloys)

Hybrid sintering techniques (pressure-assisted densification)