The stability of permanent magnet material properties is an important indicator of permanent magnet materials. Stability mainly refers to the process of changes in the magnetic properties of a magnet after magnetization under the influence of internal and external factors, which is usually expressed by the rate of change of common performance indicators. Common causes of changes in magnetic properties include temperature, time, electromagnetic fields, radiation, mechanical vibration and impact, etc. Now let's learn about the time stability of permanent magnet materials. When a magnet works or is placed for a long time, the surrounding environment (such as temperature, humidity, corrosive liquids, etc.) may cause changes in the physical and chemical properties of the magnet. After a permanent magnet is magnetized, most of its area is magnetized in a specific direction, but there are still some small magnetic domains with chaotic magnetization directions (called reverse magnetization nuclei). Under the action of various environmental factors, the original reverse magnetization nuclei will grow, and new reverse magnetization nuclei will be generated, which causes the magnetic properties of the permanent magnet to attenuate. This kind of change is generally a slow and irreversible change from the surface to the inside, which directly affects the main performance parameters of the magnet, such as remanence, coercivity or maximum magnetic energy product, and may even lead to complete failure of the magnet. This loss of magnetic properties is irreversible; even if the magnet is re-magnetized, it cannot return to the level before being placed for a long time. In recent years, with the wide application of neodymium-iron-boron permanent magnet materials in fields requiring long service life such as aerospace, electric vehicles, and high-power wind turbines, application designers have paid more and more attention to the time stability of neodymium-iron-boron permanent magnets.

1. Long-term Stability at Room Temperature

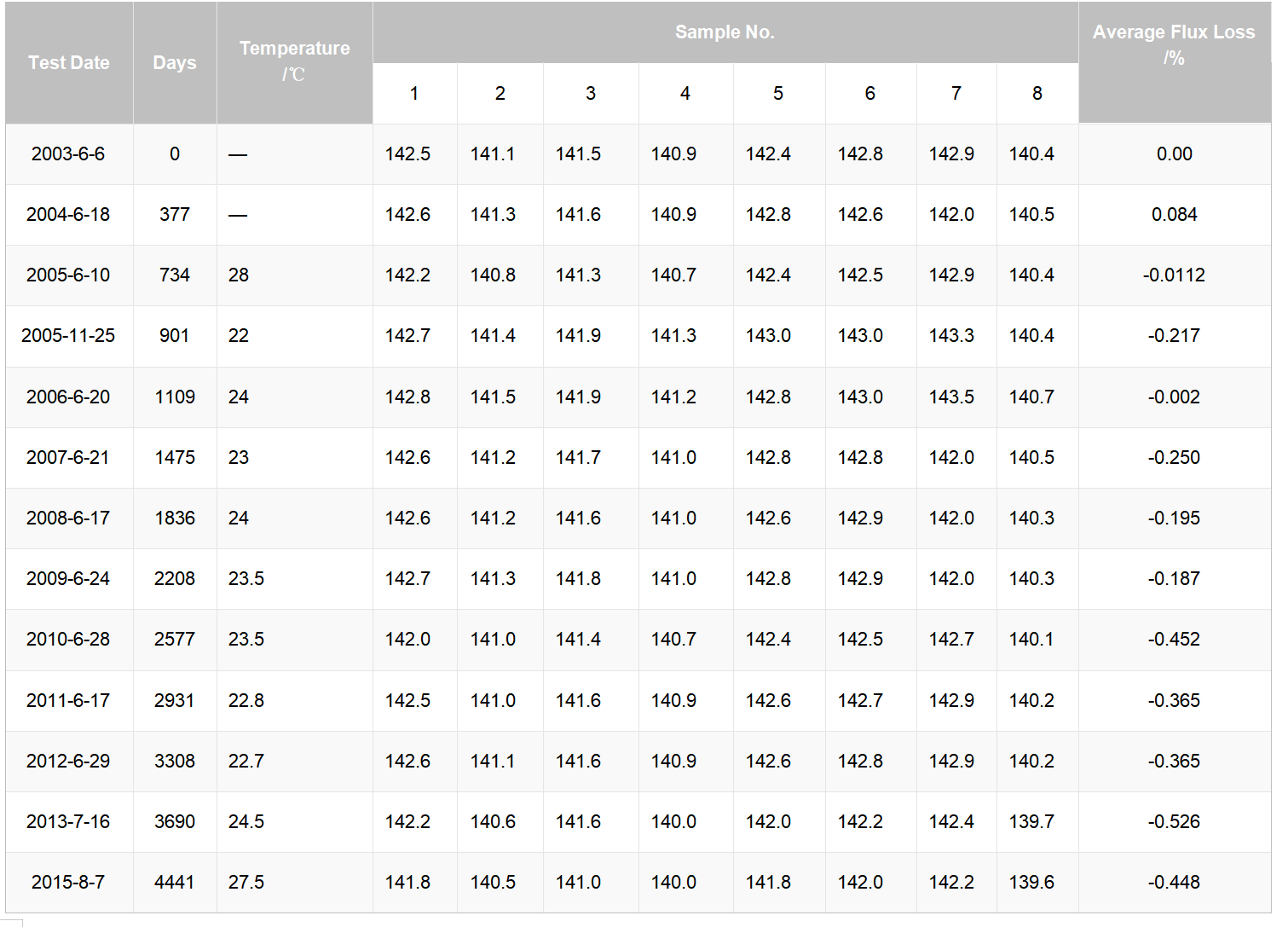

A study published by Finnish scholars in 2013 showed that sintered NdFeB magnets (HcJ = 15.6 kOe) placed at room temperature for one year (10,000 hours) had no detectable magnetization loss in samples with different Pc values (Pc = -0.33, -1.1, -3.3). Similarly, the Research Institute of 三环 (Sanhuan) also conducted a similar measurement study, which lasted for more than 12 years (4441 days). The sintered NdFeB magnets used in the experiment had an intrinsic coercivity HcJ = 18 kOe. The samples were unplated cubes with a side length of 10.2 mm, with a magnetic permeability coefficient Pc = -2 (click to learn about magnetic moment, magnetic flux and remanence to understand what Pc value is). There were 8 samples, which were directly exposed to the atmospheric environment where the laboratory was located, with the temperature ranging between 22°C and 28°C. Observations and measurements were carried out once a year within 12 years.

Table 5-1 Flux data of 8 sintered Nd-Fe-B magnet samples exposed directly to room air for 12 years

(Hcj = 18kOe (1440kA/m), Pc = -2) (Internal data of Zhongke Sanhuan Research Institute)

Notes:

1. Observed on 2009-6-24 (about 2208 days later), rust spots were visible on the surface after 6 years.

2. Observed on 2015-8-7, corner defects occurred in samples 4 and 5 due to magnetic leakage after testing.

3. When calculating the average flux loss, the flux data is converted to 23°C according to the temperature coefficient of -0.09%/°C.

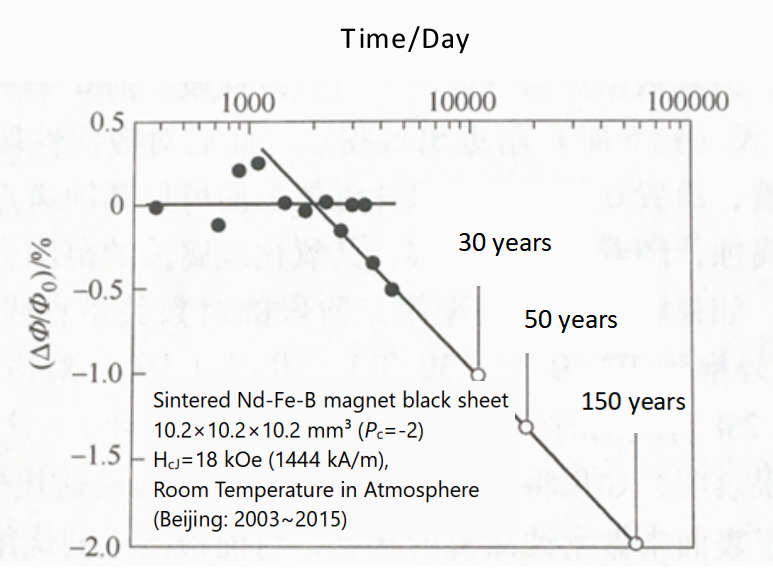

Figure 5-28 Logarithmic law of flux loss rate of sintered Nd-Fe-B magnets with Hcj = 18kOe (1440kA/m) changing with time in room temperature atmospheric environment (Pc = -2)

(Internal data of Zhongke Sanhuan Research Institute)

It can be observed from the above data that the measured relative flux loss in the first 6 years is basically insignificant, with an inflection point appearing around 2208 days (approximately the 6th year). Visually, rust spots can be seen on the surface of the black magnet after 6 years of placement, which indicates that oxidation and corrosion have begun on the surface and inside the magnet. As time goes by, the scope of oxidation or corrosion will continue to expand, and the rate of performance degradation will also accelerate significantly. In addition, the experiment extrapolated the flux loss from the currently measured 4441 days (12 years and 2 months) to 30-50 years. It is estimated that the flux loss will be less than 1% in 30 years, about 1.3% in 50 years, and the time corresponding to 2% will be approximately 150 years. (Hollow dots in the above figure)

This result indicates that if the service life of a magnet is defined as the time corresponding to a flux loss rate of 5%, the currently measured sintered NdFeB magnet, even without corrosion-resistant coating on its surface, still has an extremely long service life, which is conservatively estimated to be 30-50 years.

Typically, significant flux loss stems from oxidation or corrosion on the magnet surface, and such loss is irreversible. Among various rare earth permanent magnet materials, sintered NdFeB suffers the most severe such loss. However, through component optimization and surface protection treatments, the oxidation resistance and corrosion resistance of sintered NdFeB magnets have been greatly improved. Therefore, with the magnet surface well-protected, for sintered NdFeB with sufficiently high HcJ, its service life can completely exceed 30-50 years. (This is under the condition that the operating temperature is not exceeded)

2. Long-term stability at high temperatures

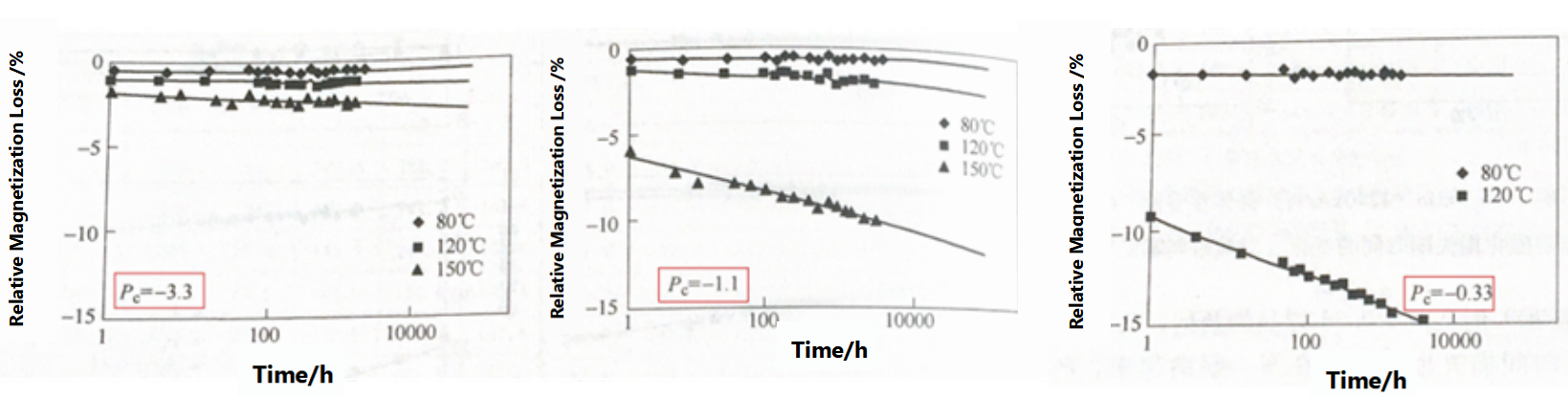

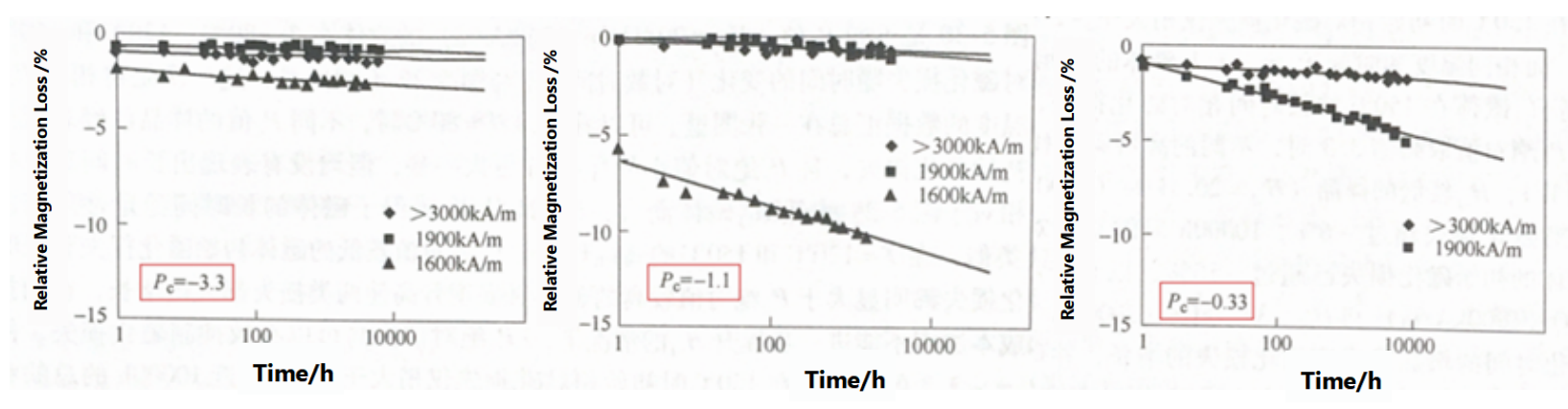

The figure below shows the change in relative flux loss over time for magnets with different Pc values and an HcJ of 20.1 kOe at 80°C, 120°C, and 150°C.

It is not difficult to see from the above figure that for magnets with the same Pc value, the higher the storage temperature, the faster the relative flux loss decreases. Magnets with a lower absolute value of Pc have significantly greater initial magnetization loss and long-term magnetization loss than those with a higher Pc value. Moreover, both types of losses increase significantly as the temperature rises. When it is impossible to further increase HcJ due to technical and cost constraints, increasing the absolute value of Pc can effectively suppress magnetization loss.

It can be seen from the time relationship of relative magnetization loss of magnets with different HcJ and different Pc at different temperatures that HcJ has a significant impact on high-temperature magnetization loss. The higher the HcJ, the lower the magnetization loss. High-temperature stability requires magnets to have a sufficiently high HcJ. At the same time, the magnetic permeability coefficient Pc can also determine the long-term high-temperature magnetization loss of magnets.